How much does a welding electrode production line cost in 2026? The short answer is: it depends on your target output in an 8-hour shift and the types of electrodes you plan to produce (for example, E6013 or E7018). In this guide, we break down welding electrode production line cost by product family and automation level, then map clear budget ranges to typical capacities (1–2 t/shift, 3–5 t/shift, 5–8 t/shift, and 8+ t/shift). You’ll first see how to choose the right line for your intended products, and then what capital to plan for major machines, so you can budget with confidence.

- What Type of Welding Electrode do you Want to Produce ?

- Welding Electrode Production Line Equipment (Spiral / Hydraulic Extruder)

- Welding Electrode Production Line Cost (Spiral / Hydraulic Extruder)

- Automation Level of Welding Electrode Production Line

- Countries Producing Welding Electrode Production Lines

What Type of Welding Electrode Do You Want to Produce?

Before budgeting, decide exactly which products you’ll make. If your scope is limited to E6013 rutile electrodes, a screw/spiral extruder is usually the most economical and fastest route. But if you plan to produce E6013 and also Special Electrodes like E7018,E8018,E9018 (low-hydrogen), alloy/stainless electrodes, or hardfacing types, choose a hydraulic coating press/extruder—it provides tighter compaction control and recipe flexibility across demanding coatings, though with higher CAPEX. This single choice has a major impact on the overall welding electrode production line cost and the quality range you can achieve. In This Article Guide to Buying the Right Welding Electrode Production Machine, you’ll find a clear breakdown of advantages, disadvantages, and core features for both production line types.If you want to know the technical details of welding electrode production, Read This Article.

Welding Electrode Production Line Equipment (Spiral / Hydraulic Extruder)

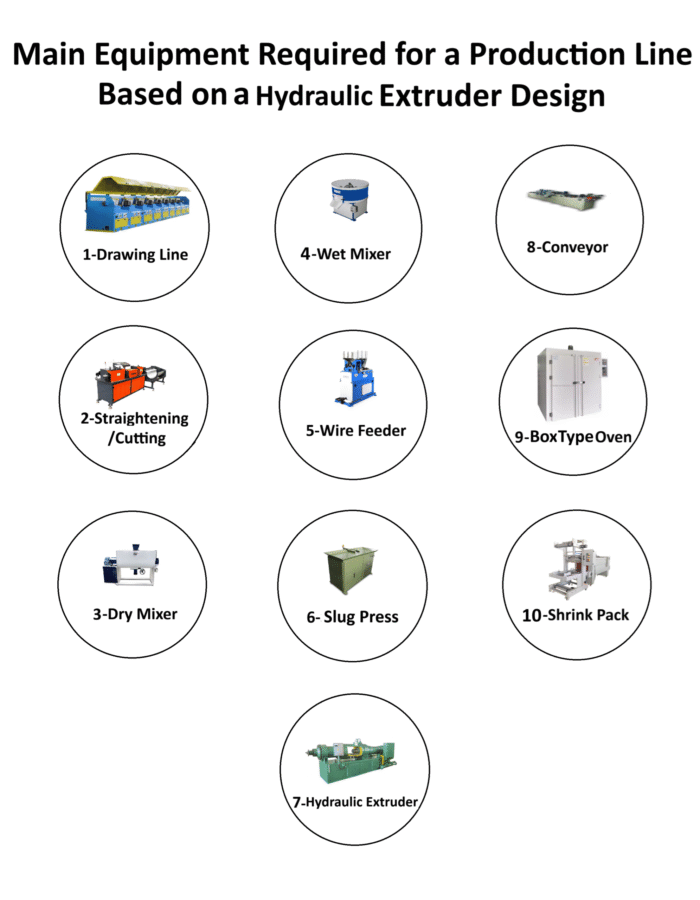

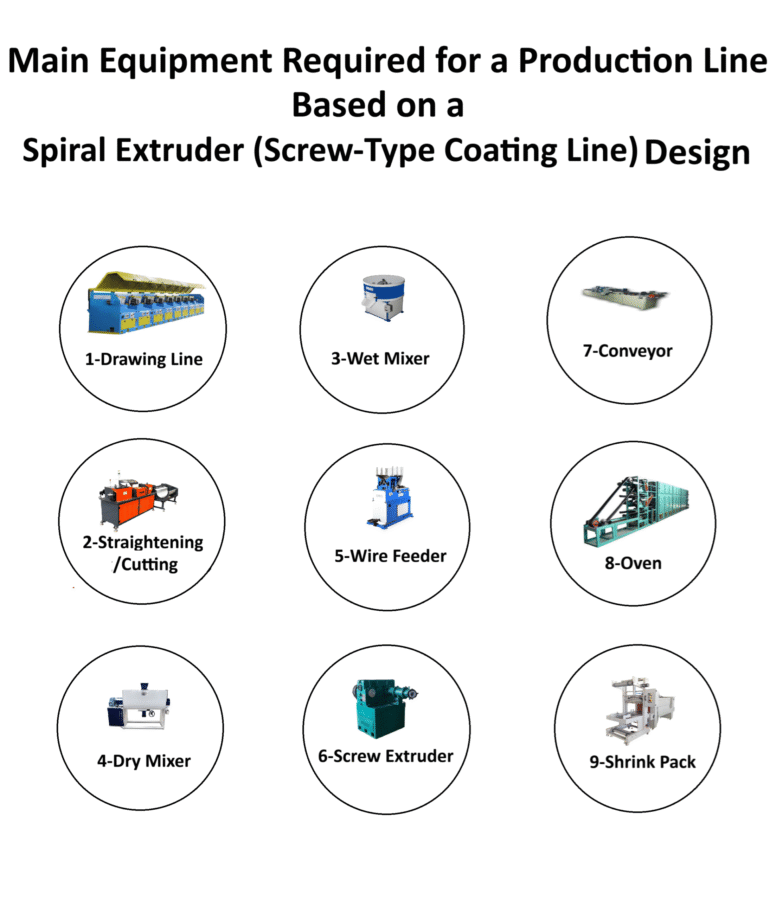

In this article, we will divide the purchase price of machinery based on the production capacity and extruder design, but the investors should know that every production line, with any capacity, requires the following production units:

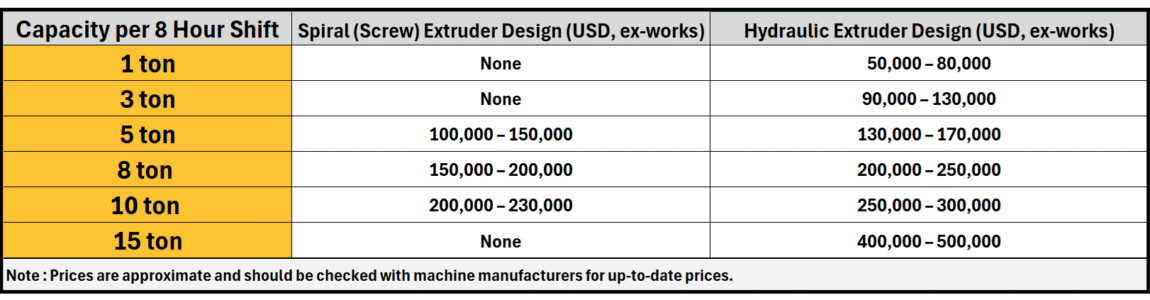

Welding Electrode Production Line Cost (Spiral / Hydraulic Extruder)

The cost of a welding electrode production line depends first on capacity per shift. A small 1–3 ton per 8-hour shift line, complete with drawing, straightening and cutting, mixers, coating line, ovens and basic packing, usually sits in the lower investment range and is suitable for new entrants or local markets. As you move to 5, 8, 10 tons and above, the price doesn’t just grow linearly: the ovens become larger and more complex, conveyors and handling systems multiply, and the electrical and mechanical infrastructure must handle much higher throughput. That’s why a 10–15 ton line can easily cost two to three times more than a basic 1–3 ton line, even if the list of machines looks similar on paper.

Technology choice is the second big cost driver. Spiral (screw-type) extruder lines are generally cheaper and are mainly used for high-volume rutile electrodes such as E6013. A complete spiral line of a given capacity will normally be noticeably less expensive than a hydraulic line with the same output, because the mechanical structure is simpler and the coating process uses a lighter press. Hydraulic extruder lines, on the other hand, require a heavy hydraulic press, slug press and often more sophisticated baking ovens, which add to the investment. The payoff is that they can produce both E6013 and more demanding electrodes like E7018, alloy and stainless grades, so investors who want a broader product portfolio usually accept the higher initial cost.

Automation Level of Welding Electrode Production Line and Its Impact on Price

Automation in welding electrode production can be classified into three levels: manual, semi-automatic, and fully automatic. A fully automatic line is not economically suitable for all investors, so it is often more practical to automate only selected parts of the process.In most cases, the first priority for automation is the packing section, and the second priority is the weighing section.

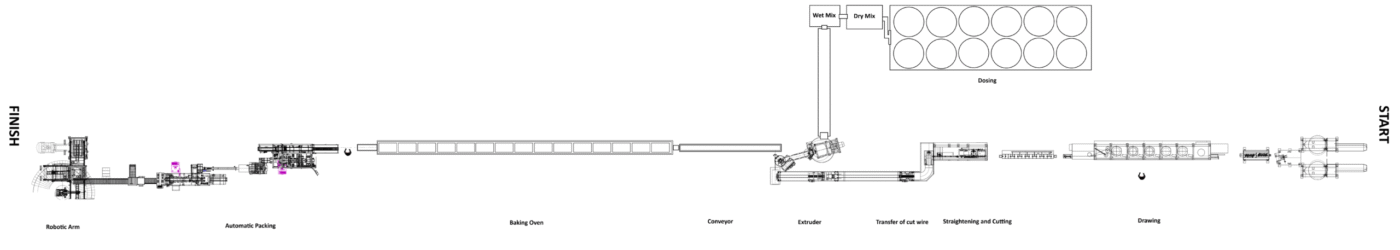

Today, there are “from A to Z” automated lines that work with minimal human intervention. In these systems, after wire drawing, straightening, and cutting, the wire is fed automatically to the extrusion area. On the other side, the raw materials are dosed in an automatic weighing system, then dry-mixed, and after adding water and binders, the coating dough is transferred to the extruder through a dedicated piping system.

After extrusion, the electrodes move by conveyor into the baking furnace, and once they are dried and baked, they are automatically counted, packed, and stacked. Even the final cartons are placed on pallets by a robotic arm. The price of such a highly automated line, with a capacity of around 2.5 tons per hour, is approximately 1.2 million USD. The layout of this line is shown below:

Countries Producing Welding Electrode Production Lines

When you look at who actually makes welding electrode production lines, the map is quite focused. Most of the complete lines (wire drawing → straightening/cutting → mixing → extrusion → baking → packing) are built in Asia–Pacific and Europe, with Asia clearly dominating on volume and exports. That’s why so many turnkey “E6013 / E7018 production line” offers you see online are tagged from this region.

In Asia, the main hubs are China and India. These countries don’t just produce electrodes – they also build and export the machinery and full plants, from simple manual/semi-automatic lines up to fully automatic systems. Their equipment is shipped a lot to the Middle East, Africa and other developing markets, because the balance of price and capacity is attractive for new investors.

On the European/Eurasian side, countries like Germany, Poland, France, Austria, Switzerland, the Czech Republic have a strong base of welding consumable manufacturers and industrial machine builders. Even when the core hardware may partly come from elsewhere, the engineering, automation, integration and process control are often done there. So in practice, investors usually choose between Asian-made lines for cost-effective capacity and European-style solutions when they want higher automation, stricter standards and deeper engineering support.

If you are curious about North America, you should know that the most reputable welding electrode manufacturing companies on this continent manufacture their own highly advanced machines.