Welding electrode production is a highly specialized field that requires deep, practical knowledge of every aspect of the industry.As an investor or as someone looking to improve an existing factory, you should first know that this is not a purely quantitative business; it is a quality-driven business.

What We Do for You in Welding Electrode Production

If You Are Planning to Start a Welding Electrode Production Plant

We support you from idea to production:

1-Feasibility, CAPEX & OPEX:

Studying your project and preparing a final report on CAPEX and OPEX based on your budget and target capacity.

2-Master plan & factory design:

Designing a master plan for a welding electrode production plant, including key architectural, civil, electrical, mechanical, and – most importantly – process criteria.

3-Cost price & profitability analysis:

Studying and reporting the final cost price and profitability of the project.

4-Know-How of welding electrode production:

Providing complete technical know-how packages for welding electrode manufacturing.

5-Machinery sourcing & negotiation:

Consulting on identifying, evaluating, and negotiating with machinery suppliers according to your required capacity, level of automation, and budget.

6-Raw material procurement:

Advising on purchasing raw materials based on know-how, with the right quality and at reasonable prices.

7-Installation, commissioning & training:

Supervising installation and commissioning of machinery, applying the correct formulations and production methods, and training your personnel.

8-Ongoing quality monitoring:

Continuously monitoring the quality of the final product and helping you evaluate and react to customer feedback.

If You Are Planning to Improve Your Current Welding Electrode Production Plant

1-Troubleshooting at all technical levels of the organization (machinery, raw materials, production process) and providing practical solutions.

2-Upgrading know-how for producing new or improved grades of welding electrodes to replace low-quality or defective products.

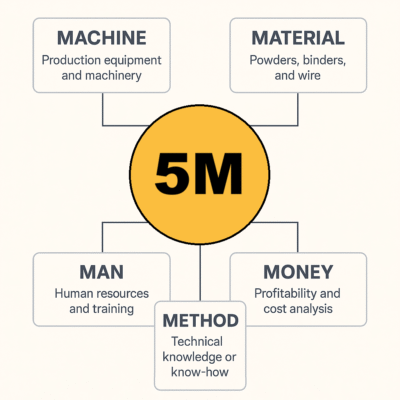

The Welding Electrode Industry Explained Through The 5M Principle

We explain the welding electrode production industry according to five key pillars: Machine, Material, Method, Man, and Money.

1. Machine

The main parts of a welding electrode production line include:

- Drawing, straightening, and cutting

- Mixer (Dry & Wet)

- Extrusion (Spiral or Hydraulic)

- Baking furnace

Your target capacity, the types of electrodes you intend to produce, and the level of automation have a direct impact on the number of production units, layout, and total machinery cost.

For more details about welding electrode production machinery, see:

Guide to Buying the Right Welding Electrode Production Machine

2. Material

Raw materials for welding electrodes are generally divided into three groups: powders, binders, and wire.

Powders include a wide range of mineral, organic, ferroalloy, and metal powders. Some are extracted from nature and then concentrated and ground; others are produced through chemical or metallurgical processes.

Binders (usually silicate-based) mainly include sodium and potassium silicate.

Wire is the heaviest component and typically accounts for 65–85% of the final product weight. It enters the factory in 1–2 ton coils, is drawn to the desired diameter, and then cut to length.

To learn more about raw materials used in welding consumables, read:

3. Method (Know-How)

The most important topic is the Method. In a professional project, machines and materials must be selected according to the method, not the other way around.

By Method, we mean technical knowledge – or Know-How.

Know-how includes:

- Formulations (coating recipes)

- Full specifications for each raw material (powders, binders, wires)

- Detailed production instructions

With the correct know-how, you:

Purchase the right raw materials according to the specifications in the know-how package.

Use a specific formula and production procedure to get the best possible quality from your machines.WESPEC can provide you with the know-how of 120 types of welding electrodes as well as 35 types of double-coated electrodes.

To fully understand the concept of Method in welding electrode manufacturing, see:

4. Man (Human Resources)

Specialized human resources are critical for the correct implementation of know-how.

From management to production engineers, quality control staff, and machine operators, everyone must receive complete and targeted training.

It is also essential to correctly assess:

- The number of personnel required in each unit

- The skills and responsibilities needed in every position

5. Money

Profitability is the main reason to enter this industry, but it must be calculated realistically.

An investor or factory owner must clearly understand:

Fixed costs (CAPEX) and variable costs (OPEX)

The cost price of each product

How to calculate and interpret the key financial parameters of the project

For more information on this topic, please refer to the CAPEX & OPEX section on our website (for example, via the CAPEX/OPEX page on wespec.net).

To know more about welding electrode production , CAPEX & OPEX, see the links below:

Welding Electrode Production Line Cost (2026): Complete Buyer’s Guide