What is a Welding Electrode?

Welding Electrode is a coated metal rod that establishes an electric arc with the workpiece; the arc’s heat melts both the electrode and the base metal, producing the joint.The length of the electrode is usually 25 to 45 cm and the diameter of the uncoated metal rod is usually 2.5 to 5 mm. The coating of this rod is made of different materials and has different functions.

Welding electrodes are also used in very simple joints, such as welding a pet cage to welding a pressure vessel. Of course, the types of electrodes used in these two applications are different. In this article, we will briefly introduce this widely used consumable.

If you want to Know About Welding Electrode Production, Read This Article.

Welding Electrode Working Mechanism

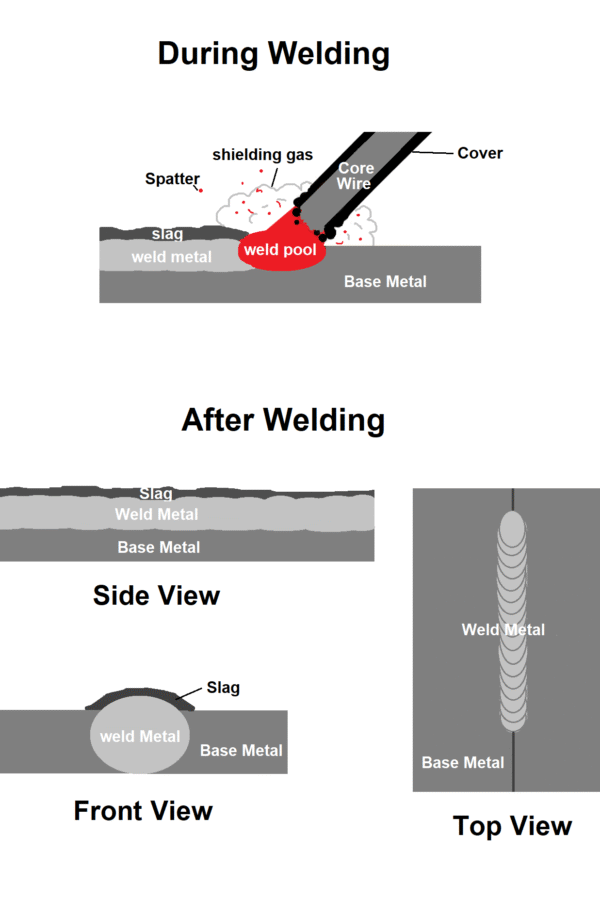

Turn on the welding machine and bring the electrode close to the metal. Because they have opposite polarity, electrons become energized and race across the tiny gap between the electrode and the workpiece. This highway, where the electrons move, is called an electric arc. The arc generates heat, which melts the electrode and the workpiece, and Creat WeldPool, after solidification, joins them together.

During the Welding, the coating burns and turns into shielding gas and a liquid “slag” that cover the hot weld, keeping out oxygen and dirt and helping the arc stay steady. The coating can also add helpful elements to the weld. After the metal cools, the slag freezes on top and can be easily removed. During welding, some spatter is also generated as waste.

Welding Electrode Types of Current

Welding can be done in three different currents. The difference in these currents is related to the direction of movement of the electrons.

DCEN (Direct Current Electrode Negative, “straight polarity”)

-

-

Electron movement: electrons flow from the electrode (−) to the workpiece (+).

-

Heat focus: most arc heat lands on the work (anode) (rule of thumb: ~2/3 at the positive side).

-

Effect: relatively deeper penetration, cooler electrode (slower melt-off), narrower bead. Good when you want heat driven into the base metal. Use only if the electrode is rated for DCEN.

-

DCEP (Direct Current Electrode Positive, “reverse polarity”)

-

-

Electron movement: electrons flow from the workpiece (−) to the electrode (+).

-

Heat focus: more heat on the electrode (anode).

-

Effect: higher melt-off rate, often wider/shallower penetration compared with DCEN, strong arc force; many SMAW electrodes are formulated to run best on DCEP—follow the rod’s spec sheet.

-

AC (Alternating Current)

-

-

Electron movement: direction reverses each half-cycle (electrode is positive, then negative).

-

Heat focus: alternates between electrode and work; net effect is more balanced heat.

-

Effect: penetration and melt-off are intermediate between DCEN and DCEP, and AC helps reduce arc blow. Requires AC-rated electrodes so the arc re-ignites cleanly at each zero crossing.

-

In an arc, electrons leave the negative side and strike the positive side, which is why the positive (anode) gets more heating. Positive ions also move toward the cathode and add some heating there. Exact penetration and bead shape still depend on the specific electrode coating and manufacturer’s polarity rating.

Types of Positions for Welding Electrodes

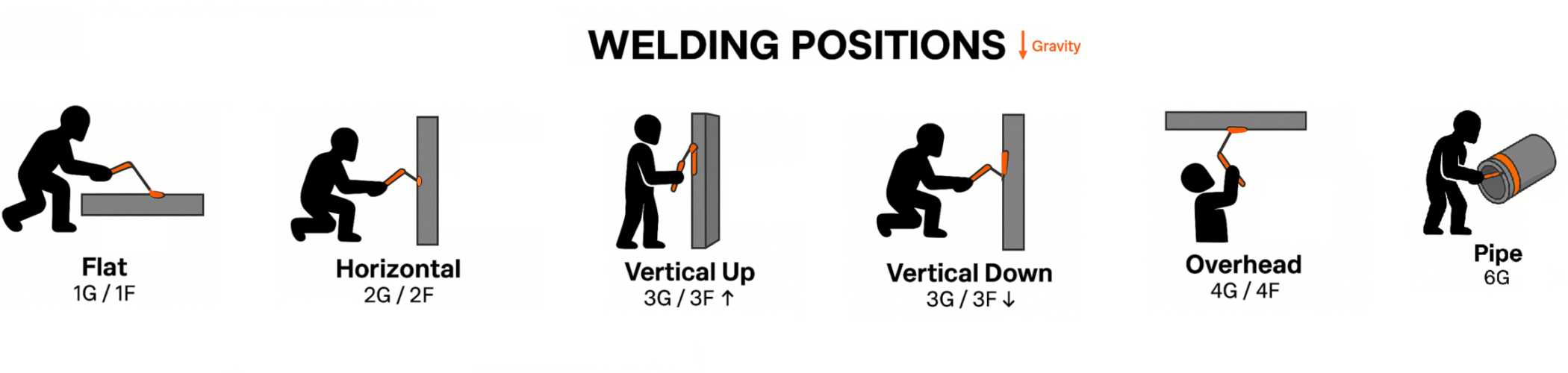

Welds aren’t always done on a flat table. The position changes how the molten metal behaves, so it affects your settings and electrode choice.

-

Flat (1G/1F): Work is on top and the weld pool sits by gravity. Easiest to learn; highest travel speed.

-

Horizontal (2G/2F): You weld along a side. The pool tends to sag—use slightly lower heat and tighter control.

-

Vertical (3G/3F): You weld up or down a wall.

-

Vertical-up gives stronger joints on thicker steel but needs slower travel and a “weave” or small triangles.

-

Vertical-down is faster on thin sheet but less penetration.

-

-

Overhead (4G/4F): You weld from below. Use fast-freezing rods/wires and short arc length so metal doesn’t drip.

Pipe work has special codes (1G, 2G, 5G, 6G). 6G (pipe fixed at 45°) is the toughest test because you use all positions in one weld.

For tricky out-of-position work (vertical/overhead), stick rods like E6010/E6011 (fast-freezing) are forgiving. For higher strength and cleaner results, E7018 works well with the right technique and storage. MIG with flux-cored wire marked “all-position” also helps.

Types of Coated Welding Electrodes

There are approximately 300 different types of welding electrodes. The difference between these electrodes is in their electrode core and different coating formulations. For example, E6013 and E7018 electrode cores are made of low-carbon steel and have different coating formulations, while the ENi-Ci electrode core wire is made of pure nickel.

Covered (SMAW) electrodes are defined by standards (AWS/ISO) into families, and each family has many classifications plus countless manufacturer variants. Think of it like this:

-

By standard family (examples):

• Carbon steel: AWS A5.1 (E6010, 6011, 6013, 7014, 7018, 7024, …)

• Low-alloy steel: AWS A5.5 (Cr-Mo, Ni-Mo, etc.)

• Stainless steel: AWS A5.4 (E308L-16, E309L-16, E316L-16, …)

• Nickel & Ni-alloys: AWS A5.11 (ENiCrFe-x, ENi-x, …)

• Cast iron: AWS A5.15 (ENi-CI, ENiFe-CI, …)

• Hardfacing: AWS A5.13 (EFeMn-, EFeCr-, etc.)

• Plus smaller non-ferrous categories in other specs.

Across these, there are dozens of standardized classifications and, in practice, hundreds of distinct commercial electrodes when you include coating variants, polarity options, moisture-resistant grades, diameters, and packaging.