Welding Electrode Coating Formula List

Introduction

The welding electrode has a coating with a combination of different materials that are pressed onto the surface of the wire. For Example a simple Typical E6013 welding electrode coating formula contains Powders Like Calcium Carbonate, Mica, Cellulose, Kaolin, Ferromanganese(MC),Silica, Potassium Feldspar ,Rutile Sand. Also The required Binder is Liquid potassium silicate, which is added in the the dry powder mixture.

However, producing high-quality welding electrodes requires more than just the formula. It involves a comprehensive technical knowledge package, including the exact specifications of each raw material—powder, binder, and wire—as well as step-by-step manufacturing instructions. This complete know-how ensures consistency in production and superior electrode performance.

Are you looking to start your own welding electrode production line or improve your current manufacturing processWelding Electrode Manufacturing Process? With decades of experience in the industry, we are offering a unique opportunity to acquire the complete technical knowledge required to produce high-quality welding electrodes. Whether you’re a startup or an established manufacturer looking to enhance your product offerings, our expertise will guide you through every step of the process. Welding Electrode Coating Formula is a part of this Know-How .This package includes important items that are describe here.

What Does this Package Include?

1-Welding Electrode Coating Formula

2-Quality Characteristics of Ingredients in Welding Electrode Coating Formula

3-Detailed Core Wire Specifications

4-Detailed Production Instructions

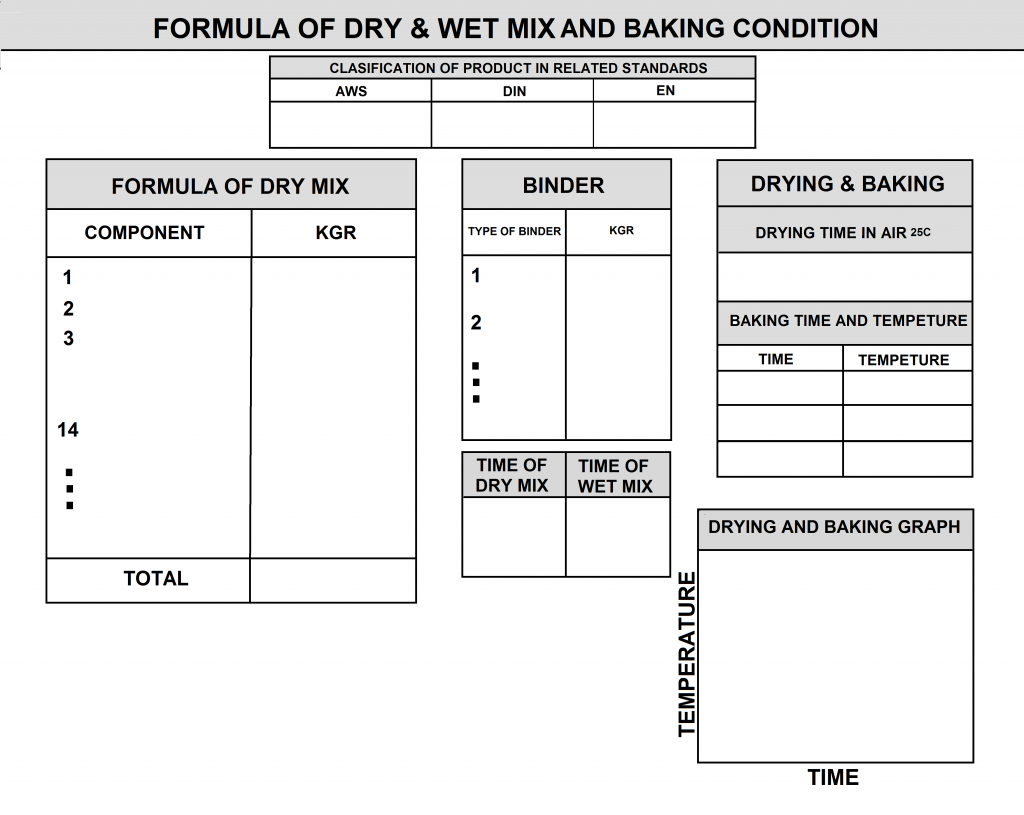

1-Welding Electrode Coating Formula

Our knowledge package provides the precise formulation required for various types of welding electrodes. For each electrode type, you’ll get the exact weight percentage of every raw material that goes into the coating formula. This detailed breakdown ensures that your product will meet industry standards and perform consistently in different welding applications.

Knowing the right proportions of flux, binders, and additives is key to producing electrodes that meet specific welding needs, such as high tensile strength or resistance to cracking. This information allows you to replicate the proven formulas we have for optimal performance.

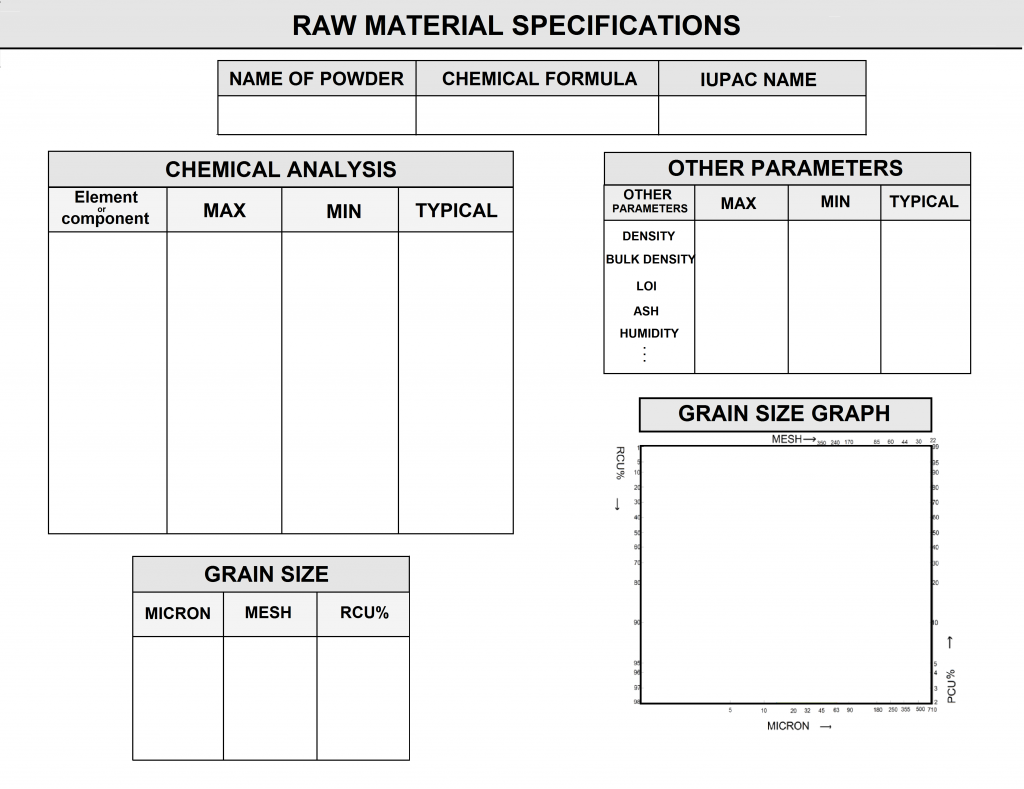

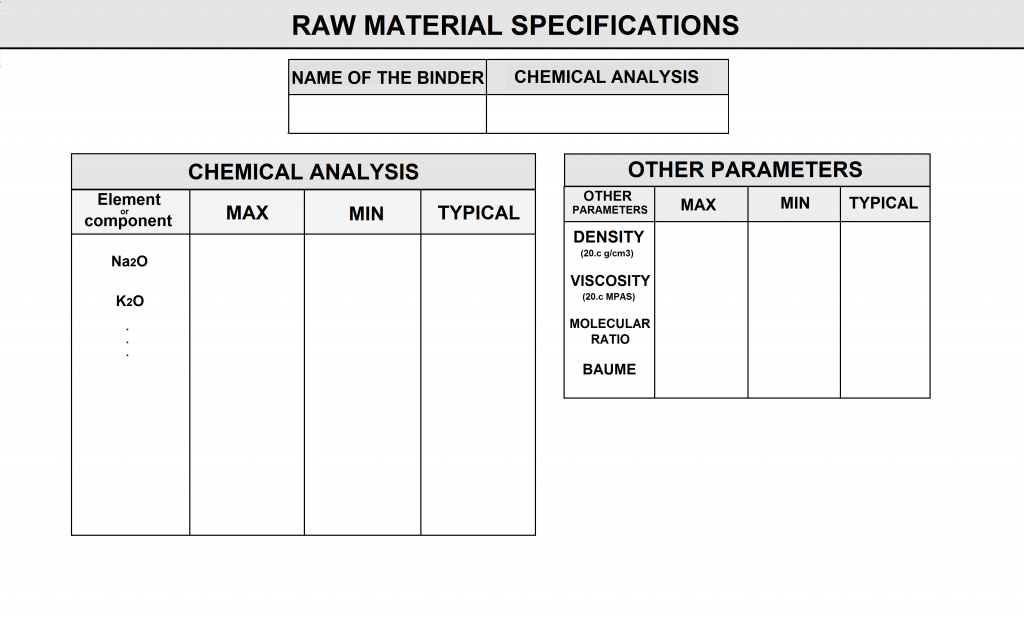

2-Quality Characteristics of Ingredients in Welding Electrode Coating Formula:

Beyond just the Welding Electrode Coating Formula, we explain the quality characteristics that each component in the coating must meet to ensure reliable and high-performance electrodes. This includes:

- The required Chemical Analysis of each material to achieve high quality of the final product and prevent unwanted reactions during welding.

- The Grain Size Analysis of each material to achieve high quality of the final product.

- Characteristics of Silicate Binders for bonding raw materials together and adhering the resulting paste to the surface of the wire.

- Information about Approved suppliers and certifications that help maintain consistent material quality.

- Storage conditions and handling tips to maintain the quality of sensitive materials like binders and fluxes.

By understanding the specific quality parameters, you can ensure that each batch of raw materials contributes to a uniform and predictable final product.

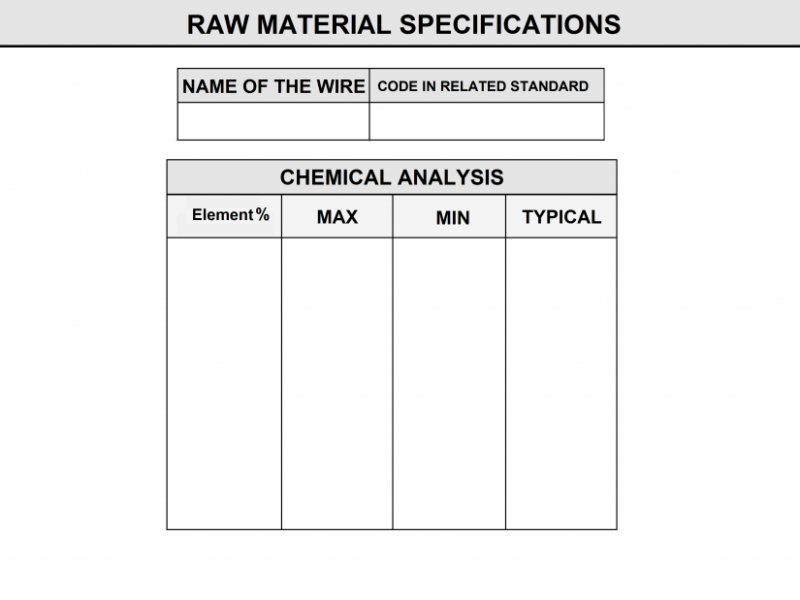

3-Detailed Core Wire Specifications:

Every welding electrode has a core wire, which plays a vital role in the performance of the electrode. Our technical knowledge package also provides the detailed specifications of the core wire used in each electrode type. This includes: Chemical analysis, Wire Diameter and Length Tolerance , Mechanical Properties, Surface Treatment.

These wire specifications ensure that the core of your electrodes meets the necessary standards for high-quality welding performance.

4-Detailed Production Instructions:

Producing welding electrodes is a complex process that requires careful control at every stage. Our package offers step-by-step production instructions to guide you through each part of the manufacturing process. This includes:

- Mixing instructions Based on Welding Electrode Coating Formula for combining raw materials into a uniform, high-quality coating paste.

- Coating procedures that outline how to apply the coating evenly and ensure it adheres properly to the electrode wire.

- Drying and Baking tips that help avoid common production defects, such as cracks in the coating or weak adherence.

- Tips for machine settings, such as temperature, pressure, and timing, to optimize each step for quality output.

Our production instructions also include practical troubleshooting tips and best practices to help you streamline your production and ensure consistent quality, batch after batch.

List of Welding Electrode Formula

The Production Formula of Welding Electrodes for Stainless and Heat-Resistant Steels

| AWS A5.4 | DIN 8556 | EN1600 |

|---|---|---|

| E 410-15 | E 13 1 B20+ | E Z 13 1 B 22 |

| E 410Ni Mo-15 | E 13 4 B20+ | – |

| E 347-16 | E 19 9 Nb R 20+ | E 19 9 Nb R 12 |

| E 318-16 | – | E 19 12 3 Nb R 12 |

| E 309 Cb-16 | E 19 12 3 Nb R 26 | E 19 12 3 Nb R 12 |

| E 347-15 | E 19 9 Nb B 20+ | – |

| E 347-16 | E 19 9 Nb R 20+ | – |

| – | E Z 16 6 Mo B20 | E Z 16 6 Mo B 42 |

| E 309 MoL-16 | E 23 13 2 L R 26 | E 23 12 2 L R 12 |

| E 309-16 | E 23 12 R 26 | E 23 12 R 12 |

| E 312-16 | E 29 9 R 26 | E 29 9 R 12 |

| E 312-16 | E 29 9 R 26 | E 29 9 R 12 |

| E 308 L-16 | E 19 9 R 26 | E 19 9L R 12 |

| E 316 L-16 | E 19 12 3 L R 26 | E 19 12 3 L R 12 |

| E 309 L-17 | E 23 12 L R 23 | E 23 12 L R 12 |

| E 309 MoL-17 | E 23 12 2 L R 12 | E 23 12 2 L R 12 |

| E 310 – 15 (Mod) | E 25 20 B 20+ | E 25 20 B 42 |

| E 2209L-16 | – | E 22 9 3 N L R 12 |

| E 308 L-15 | E 19 9L B 20+ | E 19 9L B 42 |

| E 308 L-16 | E 19 9 R 26 | E 19 9L R 12 |

| E 308 L-16 | E 19 9 R 26 | E 19 9L R 12 |

| E 309 L-16 | E 23 12 L R 26 | E 23 12 L R 12 |

| E 316 L-15 | E 19 12 3L B20+ | E 19 12 3L B 42 |

| E 309 L-15 | E 23 12 L B 20+ | E 23 12 L B 42 |

| E 347-15 | E 19 9 Nb B 20+ | – |

| E 310-16 | E 25 20 R 26 | – |

| E 308 L-17 | E 19 9 L R 23 | E 19 9L R 12 |

| E 316 L-17 | E 19 12 3 L R 23 | E 19 12 3 L R 12 |

| E 347-17 | E 19 9 Nb R 23 | E 19 9 Nb R 12 |

| E 318-17 | E 19 12 3 Nb R 23 | E 19 12 3 Nb R 12 |

| E 308 H-16 | E 19 9 R 26 | E 19 9 H R 42 |

| E 308-16 | E 19 9 R 26 | E 19 9 R 12 |

| E 307-15 (Mod) | E 18 8 Mn B 20 | E 18 8 Mn B 42 |

The Production Formula of Welding Electrodes for Cast-Irons

| AWS A5.15 | DIN8573 |

|---|---|

| EST | – |

| E NiCu -B | E NiCu-BG 22 |

| E Ni-Cl | E Ni-BG-22 |

| E NiFe-Cl | E NiFe-1BG-22 |

The Production Formula of Welding Electrodes for Hard Facing Applications

| DIN 8555 | X |

|---|---|

| E4-UM-X | (X=60 & 65S) |

| E 6-UM-X | (X=60 & 60GP) |

| E 10-GF-UM-X | (X=65GTZ & 60GR) |

| E10-UM-X | (X=60R & 55GR & 55GP & 60GR & 60GTRZ & 65GTRZ & 65GRZ & 65GTZ & 70GTRZ & 70GT) |

| E 7-UM-X | (X=200KP & 250KP) |

| E 8-UM-250-KP | – |

| E 23-UM-300-CKNPTZ | – |

The Production Formula of Welding Electrodes for Nickel Alloys

| AWS A-5.11 | DIN 1736 | Material number |

|---|---|---|

| ~ E NiCrFe-3 | EL-NiCr 15 FeMn | 2.4648 |

| ~ E NiCr Fe-2 | EL-NiCr 15 Fe Nb | 2.4805 |

| ~ E NiCrMo-3 | EL-NiCr 20 Mo9 Nb | ~ E NiCrMo-3 |

| ENiCrMo-6 | – | – |

| ENiCu-7 | EL-NiCu30Mn | – |

The Production Formula of Welding Electrodes for Gouging and Cutting

These Electrodes Are not Classified in Standards. You can Request for cutting all kinds of Carbon Steels , Stainless Steels , Aluminum Alloys , Cast Irons.

The Production Formula of Welding Electrodes for Cellulosic Electrodes

| AWS A-5.1 | AWS A-5.5 |

|---|---|

| E6010 | – |

| – | E 7010-G & A1 & P1 |

| – | E 8010-G & A1 & P1 |

| – | E9010-G & A1 & P1 |

The Production Formula of Alkaline (Basic) Welding Electrodes

| AWS A-5.1 | DIN 8529 | DIN 1913 | EN 499 | ISO 2560 |

|---|---|---|---|---|

| E-7016-H8 | E Y 42 55 Mn B H5 | – | E 42 5 B 41 H5 | – |

| E 7018-1-H4 | E SY 42 76 Mn B | – | E 42 6 B 42 H5 | – |

| E-7016-1-H8 | E Y 42 67 Mn B H5 | – | E 42 6 B 42 H5 | – |

| E 7018-H8 | – | E 51 54 B 10 | E 42 3 B 42 H10 | E 423 B 42 H10 |

| E 7018-H4R | – | E 51 55 B 5 | – | E 425 B 42 H5 |

| E 7018-H8 | – | E 51 54 B 10 | – | E 424 B 42 H10 |

| E 7018-H8 | – | E 51 54 B H 10 | E-42 3 B 42 H10 | E 423 B 42 H 1 |

The Production Formula of Low Alloy Steel Welding Electrodes

| AWS A5.5 | DIN 8529 | EN499 |

|---|---|---|

| E 12018-G-H4 | E-Y-7955 Mn 2 Ni 1 CrMo B H5 | E 89 4 Mn 2 Ni 1 Cr Mo B 42 H5 |

| E 8018-G-H4 | – | – |

| E 8018-G-H4 | E Y 5076 Mn 1 Ni B H5 | E 50 6 Mn 1 Ni B 42 H5 |

| E 9018-D1-H4 | E Y 5554 Mn Mo B H5 | E 55 3 MnMo B 42 H5 |

| E 9018-D1-H4 | – | – |

| E 10018-G-H4 | E Y 6975 Mn 2 NiCrMo B H5 | E 69 6 Mn2 NiCrMo B 42 H5 |

| E 7018-G | E Y 38 65 1 Ni Cu B | E 38 5 Z B 42 |

| E 9018-G-H4 | E SY 55 76 Mn 1 Ni Mo B H5 | E 55 6 Mn 1 NiMo B 42 H5 |

| E 7018-G-H4 | E SY 42 761 Ni B H5 | E 46 61 Ni B 42 H5 |

| E 7018-C2L-H4 | E Y 4297 3 Ni B H5 | – |

| E 9016-G-H4 | E SY 55 76 Mn 1 NiMo B H5 | E 55 6 Mn1NiMo B T 42 H5 |

| E 8018-W | – | – |

| E 8018-G | – | – |

| E 8018-C2-H4 | E Y 4687 3 Ni B H5 | – |

| E 8018-C1-H4 | E SY 42 87 2 Ni B H5 | E 46 62 Ni B 42 H5 |

| E 8018-C3-H4 | E SY 4676 1 Ni B H5 | E 46 5 1 Ni B 42 H5 |

| E 7018-C3L-H4 | E Y 4276 1 Ni B H5 | E 46 5 1 Ni B 42 H5 |

| E 9018-M-H4 | – | – |

| E 11018-M-H4 | E Y 69 75 Mn 2 NiCrMo B H5 | E 69 5 Mn2 NiCrMo B 42 H5 |

| E 12018-M-H4 | E Y 6955 Mn2 Ni1CrMo B H5 | E 69 5 Mn2 NiCrMo B 42 H5 |

| E 7016-G-H8 | E SY 42 761 Ni B H5 | E 46 6 1 Ni B 42 H5 |

| E 8016-G-H4 | – | – |

| E 8016-C1&C2&C3&C4 | – | – |

| AWS A5.5 | DIN 8575 | EN 1599 |

|---|---|---|

| E 8018-B8-H8 | E CrMo 9 B 20+ | E CrMo 9B 42 H10 |

| E 7016-A1-H8 | E Mo B 20+ | E Mo B 42 H5 |

| E 9018-B3-H8 | E CrMo 2 B 20+ | E CrMo 1 B 32 H10 |

| E 7018-A1-H8 | E Mo B 20+ | E Mo B 42 H10 |

| E 8018-B2-H8 | E CrMo 1 B 20+ | E CrMo 1 B 42 H10 |

| E 8018-B2-H4R | E CrMo 1 B 20+ | E CrMo 1 B 42 H5 |

| E 8018-B3L | E CrMo 2 B 20+ | E CrMo 2 B 42 H10 |

| E 8018-B6-H8 | E CrMo 5 B 20+ | E Z CrMo 5 B 42 H10 |

| E 8018-G-H8 | – | – |

| E 80 16-B2-H8 | E CrMo 1 B 20+ | E CrMo 1 B 42 H10 |

| E 80 18-B2L-H8 | E CrMo 1 B 20+ | E CrMo 1 B 42 H10 |

| E 90 18-B3L-H8 | E CrMo 2 B 20+ | E CrMo 2 B 42 H10 |

| E 70 18-B2L-H8 | E CrMo 1 B 20+ | E CrMo 1 B 42 H10 |

The Production Formula of Rutile Welding Electrodes

| AWS A5.1 | DIN 1913 | EN 499 | ISO 2560 |

|---|---|---|---|

| E 7014 | – | – | – |

| E 6019 | – | E 38 0 RC 11 | – |

| E 6013 | E 43 43 RR (B) 7 | E 38 2 RB 12 | E 38 2 RB 12 |

| E 6013 | E 43 22 R (C) 3 | E 380 RC 11 | E 380 RC 11 |

| E 6013 | E 51 22 RR 6 | E 420 RR 12 | E 380 RR 11 |

| E 6013 | E 43 22 R (C) 3 | E 380 RC 11 | E 380 RC 11 |

| E 6013 | E 43 33 R (C) 3 | – | E 380 RC 11 |

| E 6013 | E 43 22 R (C) 3 | E 380 RC 11 | E 380 RC 11 |

| E 6018 | – | – | – |

The Production Formula of High-Deposit Welding Electrodes

| AWS A5.1 | DIN 1913 | EN 499 |

|---|---|---|

| E7024 | E 51 22 RR 11 160 | E 380 RR 53 |

| E7028 | E 51 54 B (R) 12 160 | E 38 5 B 73 H10 |

The Production Formula of Welding Electrodes for Aluminum and Bronze

| AWS A5.3 | DIN 1732 |

|---|---|

| E1100 | EL-Al 99.5 |

| E4043 | EL-AlSi 5 |

| E Cu Sn-C | – |