What We Do at WESPEC: Empowering Your Welding Consumable Production from Concept to Creation

At WESPEC, we are committed to transforming your vision into a thriving welding consumable production line. Leveraging decades of expertise and a comprehensive suite of services, we provide technical know-how, project management, and quality management systems to support every stage of production. From formulas to factory setup, our goal is to ensure you achieve the highest standards of quality and efficiency.

Our Core Services

1. Technical Know-How for Welding Consumables

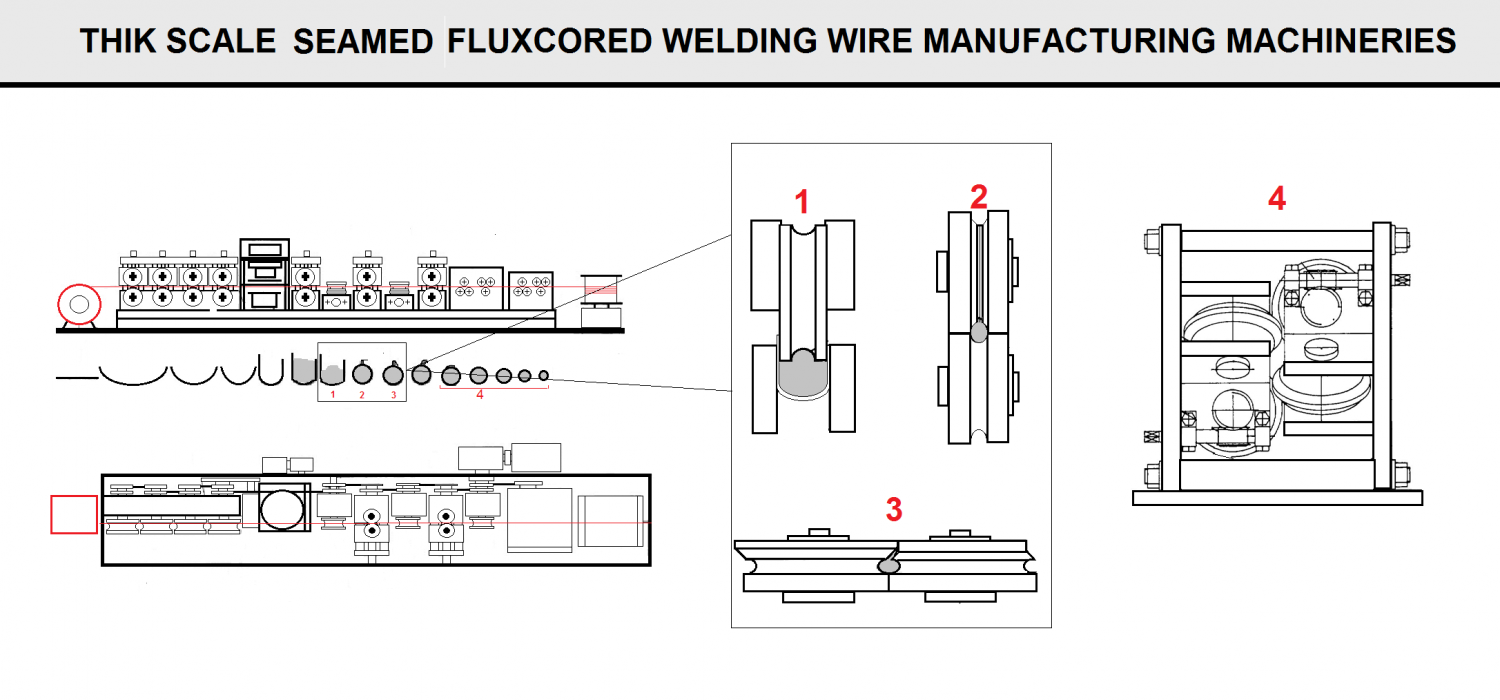

With WESPEC, you gain access to detailed, scientifically-proven knowledge for producing various welding consumables, including coated electrodes, submerged arc welding flux, MIG/MAG wires, flux-cored wires, and cutting and grinding wheels. Our know-how services cover:

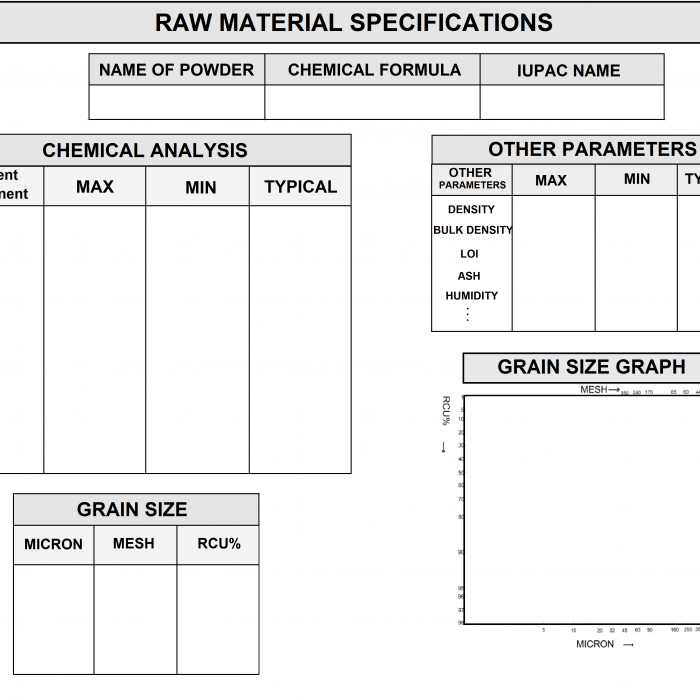

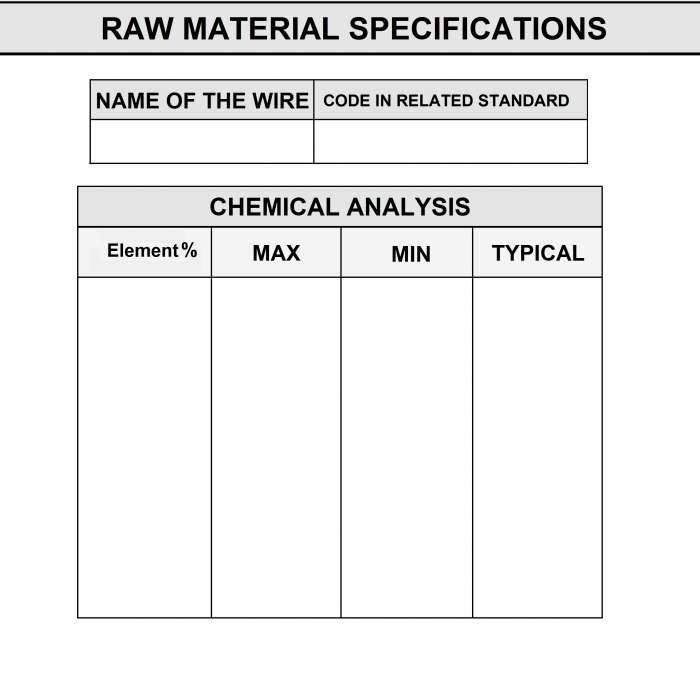

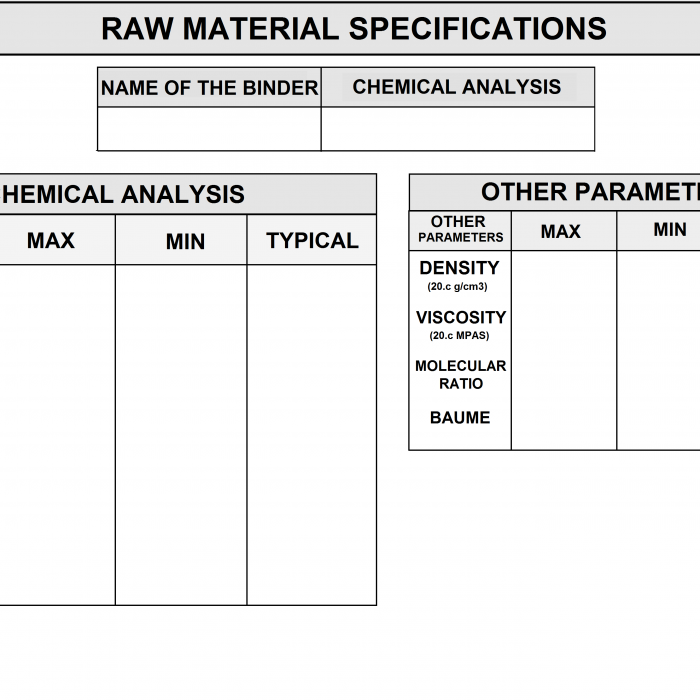

- Raw Materials Specification For Welding Consumables: Detailed Specification of Raw Materials for Manufacturing of Welding Consumables. These Materials Include Powders, Binders, Wires.

- Classified Formulations: Benefit from our precise and proven formulas for each consumable type to meet rigorous standards and client specifications.

- Production Process Guidance: Comprehensive production instructions, including machinery operation, mixing procedures, and quality checkpoints, for consistent output quality.

- Sourcing Recommendations: We provide strategic advice on sourcing top-quality raw materials and machinery to optimize cost, quality, and availability, including both local and international suppliers.

2. Project Management for Production Plants

Starting a new production line or upgrading an existing one can be complex. WESPEC simplifies this process with end-to-end project management services, helping you turn plans into production-ready facilities:

- Facility Design and Construction: From layout planning to power and resource requirements, we guide you through designing an efficient and scalable plant tailored to your production goals.

- Machinery and Equipment Selection: Receive customized recommendations on machine types, power capacity, and specifications to match your production targets.

- Laboratory Setup and Testing Protocols: We assist in setting up laboratory facilities with essential equipment for quality control, material testing, and compliance checks.

- Staff Training & Organizational Setup: Ensure a skilled and knowledgeable team with our staffing plans and in-depth training programs, designed to support both startup and operational phases.

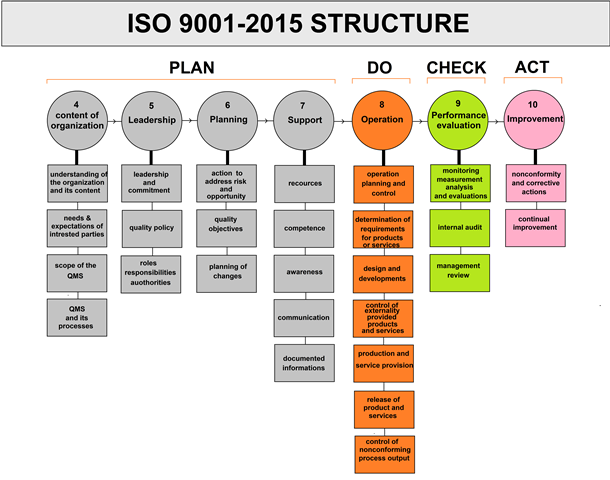

3. Quality Management System (QMS) Implementation

Achieving and maintaining high product quality is at the heart of successful welding consumable production. WESPEC’s Quality Management System (QMS) services are designed to align with ISO 9001:2015 standards, ensuring consistent quality across your operations:

- Developing Organizational Standards: We help you create essential operational instructions, from handling raw materials to final product inspection, establishing a quality-focused culture.

- Quality Control Processes: Implement robust testing, monitoring, and verification processes for every production stage, ensuring products meet and exceed industry standards.

- Continuous Improvement Audits: Through periodic audits, WESPEC identifies opportunities for improvement, helping you stay competitive and responsive to market demands.

Why Choose WESPEC?

With a commitment to technical excellence and a client-first approach, WESPEC provides a one-stop solution for welding consumable production. Whether you’re starting a new line or optimizing an existing one, our blend of technical knowledge, project execution, and quality assurance helps you achieve sustainable and profitable operations.

Let’s build your welding consumable production line together – reach out to WESPEC and begin your journey to excellence in welding technology.

Know How

A–know-how: Technical know-how in the production of all kinds of welding consumables including : coated electrodes, sub-arc welding fluxes, welding wires including GMAW & FCAW & SAW ,Electro slag consumables, Cutting and Grinding wheels.

Technical know-how includes:

1- Raw materials specifications for production of listed products ( spec of powders, binders, wires etc)

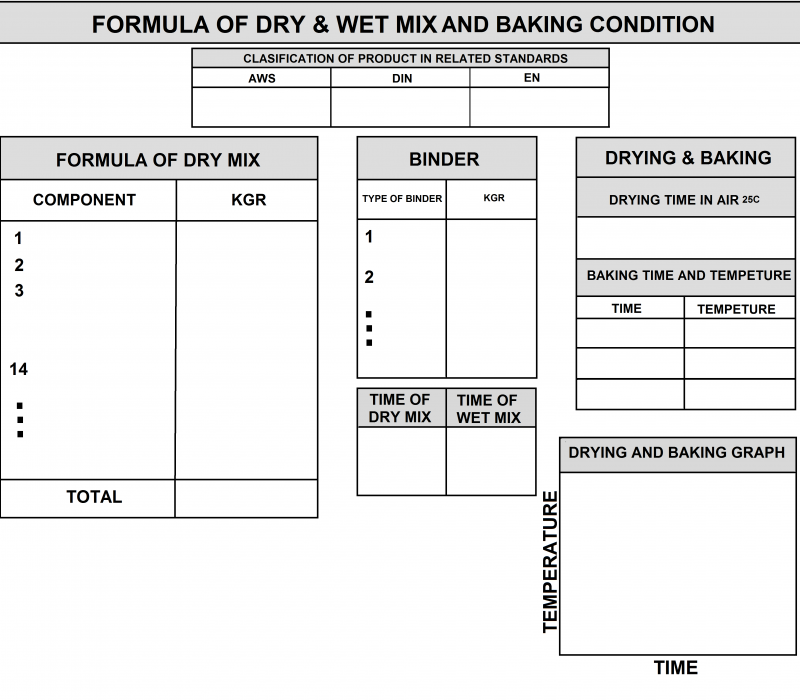

2- Formulation of dry and wet mix of Covered electrodes & Saw fluxes & Cutting and Grinding wheel

3- Production-Instruction of Covered electrodes, welding wires , Saw fluxes, Electro slag , Grinding and Cutting wheel(see Technical part).

4- Recommendation to provide the appropriate raw materials sources based on related spec.

5- Recommendation for purchasing the best manufacturing machinery based on requirements.

Project Management

B– Project Management: Ability to fully implement a manufacturing plant project includes:

1- Factory design and construction(land and buildings)

2- Power requirements (electrical ,gas ,water)

3- Determine the machine needed and design of plant lay out

4- Specify laboratory equipment required or outsourced tests

5- Specify the equipment needed to carry

6- Man power requirements

Quality Management System

C–QMS: Ability to establish a quality management system ISO9001-2015 in welding products manufacture company:

1- Develop instructions for all units in the organization

2- Develop quality indicators in all units in accordance with ISO 9001-2015 rules

3- ISO system audit and assurance of improved organization performance across units