Introduction

Quality management is the act of managing all activities and functions needed to maintain a consistent level of excellence in an organization, product or service. Quality is an essential factor that differentiates an organization from its competitors. Undertaking quality initiatives will lead to superior products or services which meet and exceed customer expectations, increase revenues and productivity for the organization.

Quality has become a global priority as many organizations have benefited from its practices. Commitment to quality is related to the intent to remain competitive and stay in business due to increased global competition. Quality management is crucial for the success of every organization, which is why many organizations engage in the process of continual improvement to secure their future. Paying attention to quality management has proven to lead to successful and competitive organizations, which are capable of offering superior products and services.

ISO 9001-2015 Sections:

The first step to make your company Standard and agile is knowing sections of ISO 9001-2015:

- Scope

- Normative References

- Terms and Definitions

- Context of the Organization

- Leadership

- Planning

- Support

- Operation

- Performance Evaluation

- Improvemen

There are 10 sections (clauses) in ISO 9001, with additional subclauses related to the Plan-Do-Check-Act system. However, only sections 4-10 contain requirements that are auditable. To successfully implement ISO 9001:2015 within your organization, you must satisfy the requirements within clauses 4-10 along with meeting customer and applicable statutory and regulatory requirements.

Summary of each section of ISO 9001:2015 Requirements:

Section 0: Introduction

This section introduces the purpose, principles and key concepts of the standard, including risk-based thinking and the process approach.

Section 1: Scope

This section defines the scope of the 9001:2015 standard. In summary, the scope includes specifying requirements for a QMS of any organization.

Section 2: Normative References

The supporting standard referenced in ISO 9001:2015 and is indispensable for its application is ISO 9000:2015 which covers terminology and fundamentals. This and other supporting standards make up the 9000 series.

Section 3: Terms and Definitions

Terminology used throughout this standard comes directly from ISO 9000:2015, Quality management systems – Fundamentals and vocabulary.

Section 4: Context of the organization

The organization shall determine external and internal issues that are relevant to its purpose and its strategic direction and that affect its ability to achieve the intended result(s) of its QMS such as:

- issues arising from technological, competitive, market, culture, social, and economic environments;

- issues related to values, culture, knowledge and performance of the organization;

- the identified needs and expectations of relevant interested parties;

- applicable legal, regulatory and other requirements to which the organization subscribes.

Defining the scope of the QMS, taking into account the organization’s strategic objectives, key products and services, risk tolerance, and any regulatory, contractual or stakeholder obligations is also part of this clause.

Section 5: Leadership

Top management shall demonstrate leadership and commitment with respect to the quality management system by:

- Taking accountability of the effectiveness of the quality management system;

- Ensuring that the quality policy and quality objectives are compatible with the strategic direction and the context of the organization;

- Ensuring that the quality policy is communicated, understood and applied within the organization;

- Ensuring the integration of the QMS requirements into the organization’s business processes;

- Promoting awareness of the process approach;

- Ensuring that the resources needed for the QMS are available;

- Ensuring that the QMS achieves its intended results;

- Engaging, directing, and supporting persons to contribute to the effectiveness of the QMS;

- Promoting continual improvement;

- Ensuring that customer requirement and applicable statutory and regulatory requirements are deter- mined and met;

- Ensuring that the risks and opportunities that can affect conformity of products and services and the ability to enhance customer satisfaction are determined and addresses;

- Establishing, reviewing and maintaining the quality policy;

- Ensuring that the responsibilities and authorities for relevant roles are assigned, communicated and understood within the organization.

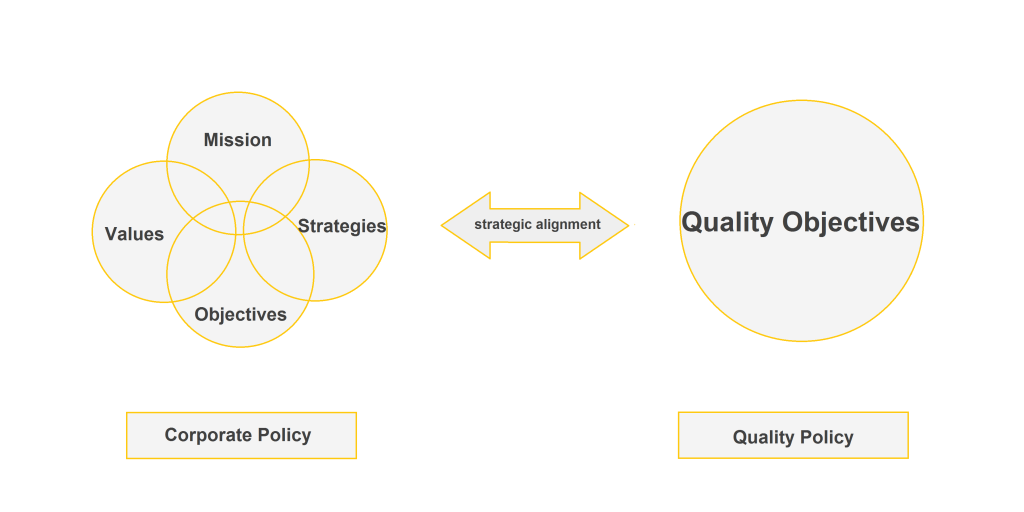

Section 6: Planning for the quality management system

This is a critical stage as it relates to establishing strategic objectives and guiding principles for the QMS as a whole. The intent of the organization to treat the risks identified and/or to comply with the QMS requirements can be expressed through the QMS objectives. The quality objectives shall:

- be consistent with the quality policy;

- be measurable;

- take into account applicable requirements;

- be relevant to conformity of products and services and the enhancement of customer satisfaction;

- be monitored, communicated and updated as appropriate.

- Select and define a risk assessment methodology.

- Demonstrate that the selected methodology will provide comparable and reproducible results

- Define criteria for accepting risks and identify acceptable levels of risk.

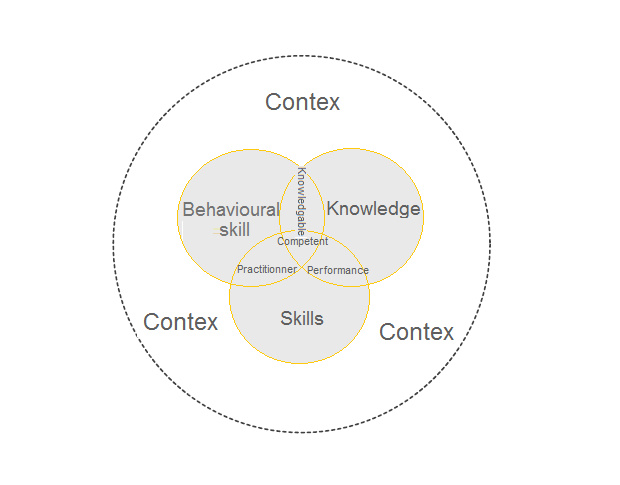

Section 7: Support

The day-to-day management of an effective quality management system relies heavily on using the appropriate resources for each task. These include having competent staff with relevant (and demonstrable) training and supporting services, awareness and communication. This must be supported by properly managed documented information.

Both internal and external communications of the organization must be considered in this area, including the format, the content and the proper timing of such communications.

The requirements on the creation, update and control of documented information are also specified in this clause.

Section 8: Operation

After planning the QMS, an organization must put it into operation. This clause includes:

>>Operational planning and control: This activity includes implementation of plans and processes that lead the organization towards meeting the quality management system requirements. Additionally, this clause requires from organizations that they establish controls which help in preventing any deviation from the quality policy, objectives, and legal requirements.

After the requirements have been established, the organization should control the planned changes and review the unintended changes to mitigate any adverse effect. All the processes within the organization, including outsourced processes should be controlled.

>>Determination of requirements for products and services: The organization shall determine all the requirements related to products and services, such as customer requirements, organizational, statutory and regulatory, and ISO 9001:2015 requirements. The organization shall establish an effective customer communication process. After all the requirements have been determined, they must be reviewed to ensure contract or order requirements differing from those previously defined are resolved.

>>Design and development of products and services: This activity requires that organizations establish, implement and maintain a design and development process.

>>Control of externally provided products and services: The organization shall ensure that externally provided processes, procedures, and services conform to specified requirements. This clause applies to both physical products and consumed services related to the end product of the organization. An organization will need to apply a risk-based approach and determine the type and extent of controls necessary.

>>Production and service provision: Businesses should control delivery and post-delivery activities to ensure that the product and service provision is implemented under controlled conditions. This requirement expects from organizations to have traceability mechanism to identify process outputs, protect and safeguard the property belonging to customers or external providers, and to preserve the products and services.

>>Release of products and services: Organization should verify conformance to acceptance criteria when re-leasing the products and services. Acceptance criteria is the criteria set by the organization specifying certain indicators or measures employed in assessing the ability of a component, structure, or system to perform its intended function. Setting the criteria before initiating the project makes its development much easier. Each organization should define its own criteria in order to ensure a higher level of customer satisfaction.

>>Control of nonconforming process outputs, products and services: This activity involves identification of control of products and services to ensure that they comply with the stated requirements. Nonconforming processes, products and services have to be corrected, segregated, or returned. Additionally, the standard requires that organization inform the customers for the nonconforming products to prevent customer dissatisfaction.

Section 9: Performance Evaluation

Once the QMS is implemented, ISO 9001 requires permanent monitoring of the system as well as periodic reviews to:

- demonstrate conformity of products and services to requirements;

- assess and enhance customer satisfaction;

- ensure conformity and effectiveness of the quality management system;

- demonstrate that planning has been successfully implemented;

- assess the performance of processes;

- assess the performance of external providers

- determine the need or opportunities for improvements within the quality management system.

Section 10: Improvement

Continual improvement can be defined as all the actions taken throughout the organization to increase effectiveness (reaching objectives) and efficiency (an optimal cost/benefit ratio) of processes and controls to bring increased benefits to the organization and its stakeholders. An organization can continually improve the effectiveness of its management system through the use of the quality policy, objectives, and audit results, analysis of monitored events, indicators, risk analysis, corrective actions and management review.

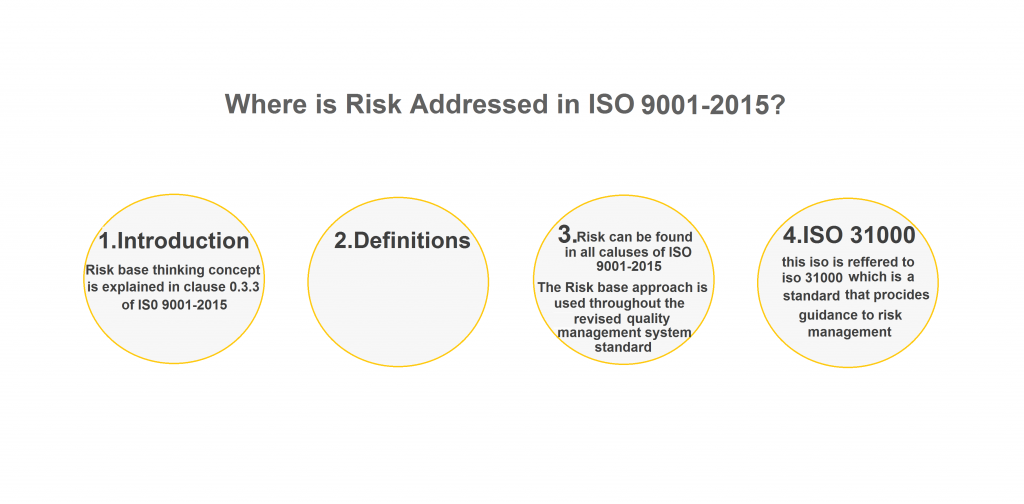

Risk based approach

By undertaking risk-based approach, any organization can become more proactive rather than only reactive to changes in the context in which it evolves. It can thus better prevent or reduce undesired effects and can then better promote continual improvement. Preventive action becomes rather ‘automatic’ when a management system is risk-based.

In this meaning, risk-based approach is one of the major changes in the new version of ISO 9001. The 9001:2015 has replaced the ‘preventive action’ concept with a set of requirements on managing risk. Some risk analysis was implicit in the old version of the standard through preventive action analysis, but the new version makes risk more explicit by incorporating it throughout the quality management system.

The risk-based approach came as a result of the incorporation of Annex SL into ISO 9001:2015. It plays an important part in the new version of the standard, and it has clear clauses to determine risks and take actions. Even though the concept of ‘risk’ is new in ISO 9001:2015, many organizations already have an approach in place to manage risk. They have to align it with ISO 9001:2015 requirements and show that the requirements are met.

Risk can be found in the following clauses of ISO 9001:

- Clause 4 (Context of the organization) – the organization is required to determine the risks which may affect the quality management system.

- Clause 5 (Leadership) – top management is required to ensure that requirements from clause 4 are followed.

- Clause 6 (Planning for the quality management system) – the organization is required to take actions towards risk and opportunity identification.

- Clause 8 (Operation) – the organization is required to implement processes to address risks and opportunities.

- Clause 9 (Performance evaluation) – the organization is required to monitor, measure, analyses and evaluate the risks and opportunities.

- Clause 10 (Improvement) – the organization is required to continually improve its processes while responding to changes in risk.

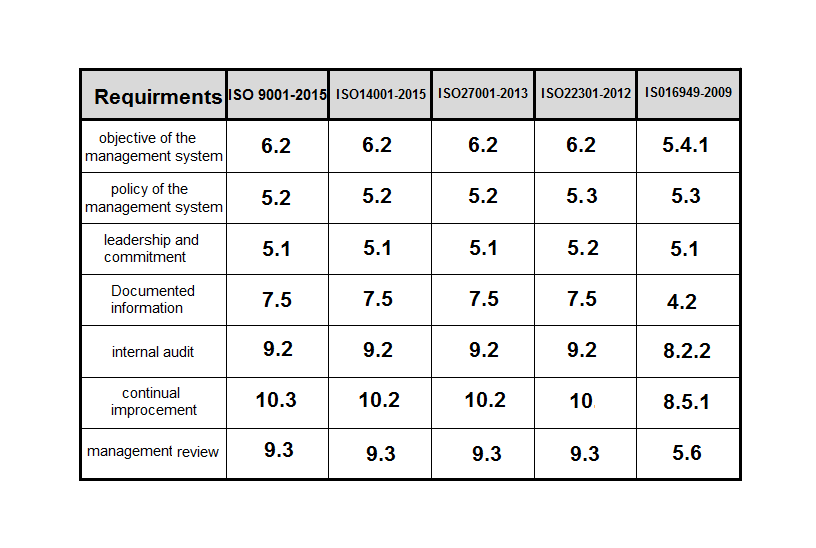

Link between ISO 9001:2015 and other standards

Various standards such as ISO 9004 and ISO 9000 are used to complement ISO 9001:2015. ISO 9004 provides guidance to organizations to support the achievement of sustained success by a quality management approach. ISO 9004 standard provides additional guidelines on customer focus, defect prevention, cost control, process approach, documentation, purchasing, informed decision-making, training and employee motivation. In addition, ISO 9000 discusses definitions and terminology and is used to clarify the concepts used by the ISO 9001 and ISO 9004 standards.

Other standards that are closely linked to ISO 9001:2015 are sector specific standards. These standards are meant to complement quality management system in defining best practice within certain sectors, and tackle the issues which ISO 9001 does not cover. Sector specific quality management standards include ISO 16949 (automotive industry), AS 9100 (aerospace industry), TL 9000 (telecommunications industry), ISO 13485 (medical devices), ISO 29001 (oil and gas industry), and so on.

Integration with other management systems

General requirements presented in the table below are commonly stated in any management system and relate to determining objectives, applying them according to the organization’s habits and needs, keeping them alive based on a strong management commitment, monitoring and reviewing, supporting the management system by good documentation, regular ‘health-checks’ via internal or external audits and to gain benefits through continual improvement as achieved by a regular management review.

The table below shows how a QMS can be considered jointly with other management systems. This will authorize the organization to envision “combined audits” in order to achieve their compliance goals with adequate effort and budget.

Quality Management – the business benefits

As with all major undertakings within an organization, it is essential to gain the support and sponsorship of executive management. By far, the best way to achieve this is to illustrate the positive gains of having an effective quality management process in place, rather than highlighting the negative aspects of the contrary.

Today, an effective quality management is not about being forced into taking action to address external pressures, but its importance relies on recognizing the positive value of quality good practice being embedded throughout your organization.

- Improved organizational effectiveness and efficiency;

- Improved understanding of the business as gained through risk identification and analysis

- Operational resilience which results from implementing risk reduction

- Downtime reduction due to the identification of alternative processes and workarounds

- Protection of stakeholder value

- Increase customer and employee satisfaction;

- Increased market share and profit;

- Improved organizational culture;

- Enhanced continuous improvement;

- Process improvement; and

- Avoidance of liability actions.

Quality management principles

ISO 9001:2015 is based on seven quality management principles that can be used by top management to lead the organization towards improved performance.

- Customer focus: Organizations depend on their customers and therefore should understand current and future customer needs, meet customer requirements and strive to exceed customer expectations.

- Leadership: Leaders establish the unity of purpose and direction of the organization. They should cre- ate and maintain the internal environment in which people can become fully involved in achieving the organization’s objectives.

- Engagement of People: People at all levels are the essence of an organization and their full involvement enables their abilities to be used for the organization’s benefit.

- Process approach: A desired result is achieved more efficiently when activities and related resourceare managed as a process

- Improvement: Improvement of the organization’s overall performance should be a permanent objective of the organization.

- Evidence-based Decision Making: Effective decisions are based on the analysis of data and information.

- Relationship Management: An organization and its interested parties are interdependent and a mutu- ally beneficial relationship enhances their ability to create value.

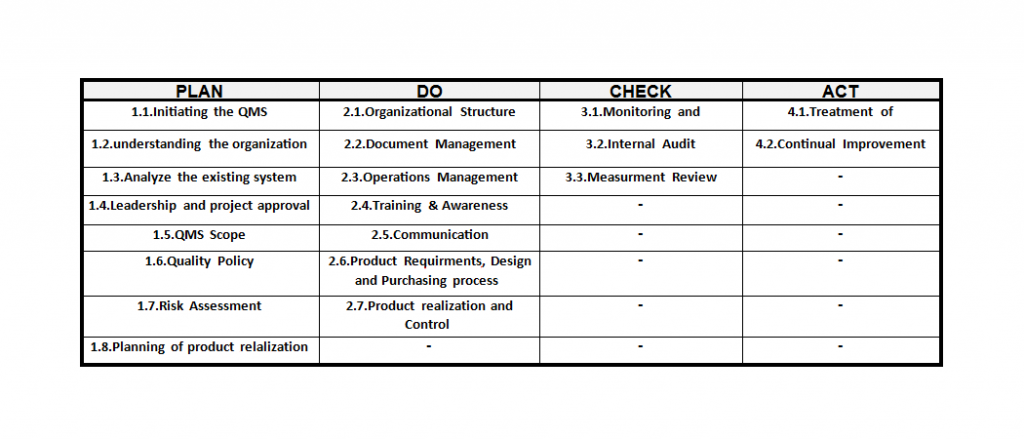

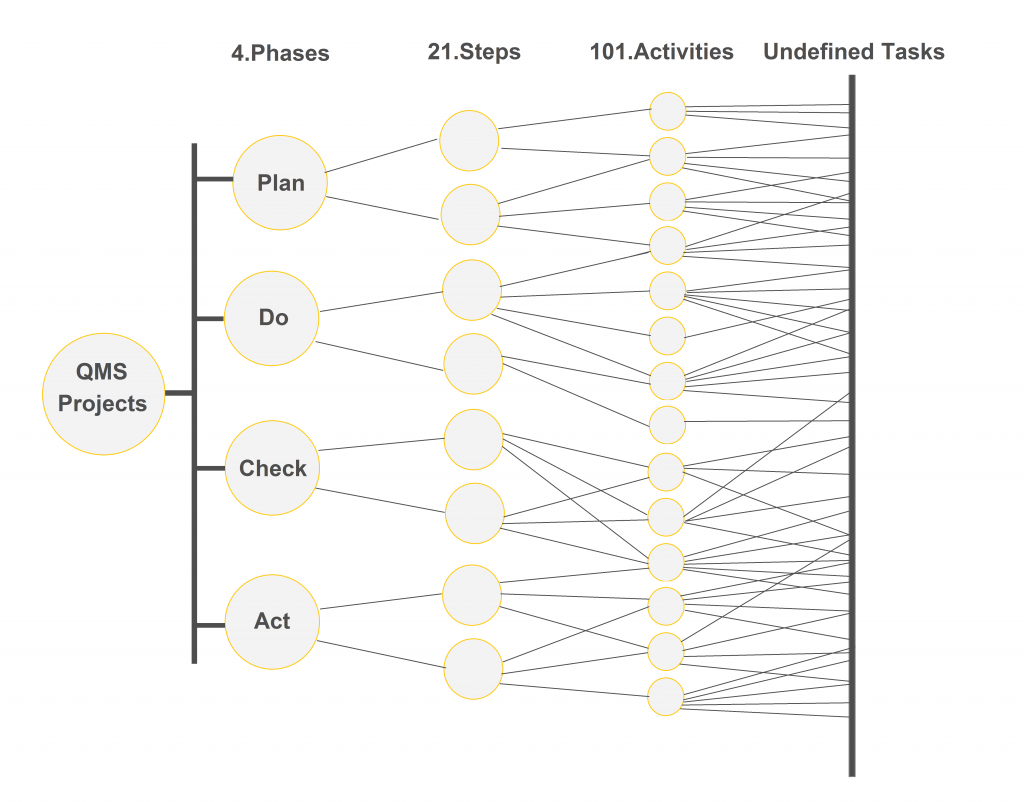

Implementation of a QMS with WESPEC methodology

Making the decision to implement a Quality Management System based on ISO 9001 may often be a simple one, as the benefits are well documented. It is important to follow a structured and effective methodology to cover all the minimum requirements for the implementation of a quality management system. Most companies now realize that it is not sufficient to implement a generic, “one size fits all” quality management program. For an effective implementation methodology, organizations need to take into account specific risks that would impact the quality performance. A more difficult task is the compilation of an implementation plan that balances the requirements of the standard, the business needs and the deadline to become certified.

There is no single blueprint for implementing ISO 9001 that will work for every company, but there are some common steps that will allow the organization to balance the often conflicting requirements and prepare for a successful certification audit. Whatever methodology used, the organization must adapt it to its particular context (requirements, size of the organization, scope, objectives, and so on).

WESPEC has developed a methodology for implementing a management system.This methodology is based on the guidelines of ISO standards and also meets the requirements of ISO 9001.

Certification of Organizations

The usual path for an organization that wishes to be certified against ISO 9001 is the following:

1. Implementation of the management system: Before being audited, a management system must be in operation for some time. Usually, the minimum time required by the certification bodies is 3 months.

2. Internal audit and review by top management: Before a management system can be certified, it must have had at least one internal audit report and one management review.

3. Selection of the certification body (registrar): Each organization can select the certification body (registrar) of its choice.

4. Pre-assessment audit (optional): An organization can choose to perform a pre-audit to identify any possible gap between its current management system and the requirements of the standard.

5. Stage 1 audit: A conformity review of the design of the management system. The main objective is to verify that the management system is designed to meet the requirements of the standard(s) and the objectives of the organization. It is recommended that at least some portion of the Stage 1 audit should be performed on-site at the organization’s premises.

6. Stage 2 audits (On-site visit): The Stage 2 audit objective is to evaluate whether the declared management system conforms to all requirements of the standard is actually being implemented in the organization and can support the organization in achieving its objectives. Stage 2 takes place at the site(s) of the organization’s sites(s) where the management system is implemented.

7. Follow-up audit (optional): If the auditee has non-conformities that require additional audit before being certified, the auditor will perform a follow-up visit to validate only the action plans linked to the non- conformities (usually one day).

8. Confirmation of registration: If the organization is compliant with the conditions of the standard, the Registrar confirms the registration and publishes the certificate.

9. Continual improvement and surveillance audits: Once an organization is registered, surveillance activities are conducted by the Certification Body to ensure that the management system still complies with the standard. The surveillance activities must include on-site visits (at least 1 per year) that allow verifying the conformity of the certified client’s management system and can also include: investigations following a complaint, review of a website, a written request for follow-up, etc.

The All-In-One Easy 9001 Toolkit is an ISO 9001 package that enables beginners to easily implement ISO 9001:2015 in your company and quickly achieve ISO 9001 certification. It only takes 5 Easy Steps with this comprehensive ISO 9001 solution that’s complete with everything you need.

All-In-One- Comprehensive Solution

The search is over: we give you the tools you need for ISO 9001! The All-In-One 9001 Toolkit is a complete and integrated ISO 9001 package that includes:

Every single component of the All-In-One Easy 9001 Toolkit is designed for ease of use so that you don’t need any prior ISO 9001 knowledge to implement an ISO 9001 quality management system by yourself in-house. The detailed guides and instructions are easy to understand, easy to use and free of unnecessary steps and requirements; the documentation templates are straight-forward, pre-written and only need to be customized following the included customization instructions; the forms and checklists not only make it easy to set up your ISO 9001 quality management system but also to meet all ISO 9001:2015 requirements. In addition, our 9001 Toolkit contains all you need to implement your ISO 9001 quality management system so you won’t spend time and efforts finding the necessary tools.

You won’t be alone with your ISO 9001 project: the All-In-One 9001 Toolkit comes with unlimited free access to our senior ISO 9001 experts to help you. With our All-In-One Easy 9001 Toolkit even beginners can implement ISO 9001.

What is included?

All of the 26 components and over 65 individual tools below are included in the All-In-One 9001 Toolkit to achieve ISO 9001 certification in only 5 easy steps.you can receive full version of this toolkit by working with WESPEC.

Step One: Getting Started

1)Easy 9001 Implementation Guidebook

The “Easy 9001 Implementation Guidebook” is your step-by-step guide for the entire ISO 9001 implementation project, starting from the very beginning until you reach ISO 9001 certification. This guide keeps the ISO implementation process simple: it focuses on getting things done to quickly reach your goal of ISO certification without unnecessary paperwork, layers of “task teams” and other hurdles. The guidebook is very easy to follow, and there is no prior knowledge of ISO 9001 required. The following chapters are included:

Getting Started

Planning the ISO 9001 Project

Training

ISO 9001 Documentation Development

ISO 9001 Implementation and Training

Writing Work Instructions

Internal ISO 9001 Audits

ISO 9001 Certification

Marketing

Maintaining ISO 9001 Certification

2)Executive Summary of ISO 9001 and its Benefits

The “Executive Summary of ISO 9001 and its Benefits” is a concise introduction to ISO 9001 that gives executive management the necessary understanding of ISO 9001 and its benefits to the company. The summary focuses on what executive management need to know without wasting valuable time. The following topics are covered:

The Foundation of ISO 9001

ISO 9001 Summary

ISO 9001 Facts

ISO 9001 Benefits

Management Involvement

3)Position Description for the ISO 9001 Management Representative

The “Position Description for the ISO 9001 Management Representative” includes a comprehensive description of job requirements, work environment and qualifications of your company’s ISO 9001 Management Representative (that’s how the the person in charge of ISO 9001 has traditionally been called). The purpose of this document is to provide you with an overview of the requirements of the ISO 9001 Management Rep position, potentially advertise the position, select the ideal candidate, and document the position requirements for this crucial ISO 9001 position.

4)Training Plan for the ISO 9001 Management Representative

The proper planning for training is a crucial ISO 9001 requirement, and this training plan makes it easy to meet the requirements. The “Training Plan for the ISO 9001 Management Representative” ensures that the important training for the ISO 9001 Management Rep is properly planned, conducted and documented (ISO 9001 auditors routinely ask about this document).

5)Employee Memo on ISO 9001

Use this memo to introduce your employees to the upcoming ISO 9001 implementation at your company. This memo will give your employees a basic understanding of ISO 9001, tell them what is expected of them, and – most importantly – alleviate your employees of any fear regarding ISO 9001 they may have. In short, the “Employee Memo on ISO 9001” will make the ISO 9001 implementation smoother for you. In addition, you may use this memo to demonstrate to your ISO 9001 auditor that you provided basic ISO 9001 training to your employees.

6)ISO 9001:2015 Compliance and Gap Analysis

This comprehensive checklist is used to determine the level of ISO 9001 compliance at your company prior to the start of the ISO 9001 implementation. The purpose of this gap analysis is to identify the functional areas in your company that require attention in order to become ISO 9001 compliant. Another use of the “ISO 9001:2015 Compliance and Gap Analysis” is to demonstrate to your company’s management where ISO 9001 will lead to tangible improvements. The “ISO 9001:2015 Compliance and Gap Analysis” evaluates your company against 285 criteria.

7)Registrar Interview Checklist

This checklist is an invaluable tool to help you choose the ideal ISO 9001 registrar (the organization that issues your ISO 9001 certificate) for your company’s individual circumstances. The “Registrar Interview Checklist” contains 24 important selection criteria that will have a significant impact on the success and on the cost of your ISO 9001 certification.

Step Two: Documentation Development

8)ISO 9001 Quality Policy (Template & Instructions)

The ISO 9001 quality policy is the most top level document of all the ISO 9001 required documents; it sets the corporate policy on quality for the company. The ISO 9001 standard includes specific requirements for the quality policy. To make it easy for you to establish your company’s quality policy in accordance with all ISO 9001 requirements, we are providing you with a prewritten template that you can easily modify to fit your company’s circumstances. Detailed customization instructions are included.

9)Process Flowchart (Template & Instructions)

The “Process Flowchart” is designed to describe the key processes and the overall process flows of most companies. The result: an easy way to meet the ISO 9001:2015 requirements for “a description of corporate processes and their interaction” as you may not even need to customize our “Process Flowchart”. If however, you chose to customize it, simply follow the included step-by-step instructions.

10)Scope Statement (Template & Instructions)

The “Scope Statement” describes the scope, boundaries and exclusions of your ISO 9001 quality management system according to several specific ISO 9001:2015 requirements. This template applies all pertinent requirements; detailed, word-by-word customization instructions are included.

11)ISO 9001 Quality Manual

The “ISO 9001 Quality Manual” summarizes your company’s ISO 9001 quality management system and contains the overall requirements. With the newest revision of the ISO 9001 standard (ISO 9001:2015), the ISO 9001 Quality Manual is no longer an explicitly required document (though some auditors argue that one only gained the flexibility to call it by another name). We include the ISO 9001 Quality Manual in this toolkit because it can be a very useful marketing tool, and customizing it is extremely easy and fast.

12)Customization Instructions – ISO 9001 Quality Manual

The “Customization Instructions – ISO 9001 Quality Manual” make it very easy and fast to adapt the ISO 9001 Quality Manual to your company’s circumstances – just follow the instructions step-by-step and you might be done in less than one hour!

13)ISO 9001 Procedures Manual

The “ISO 9001 Procedures Manual” is the very core of your ISO 9001 documentation. It contains all the procedures required for your ISO 9001 quality management system. The structure and numbering system reflects that of ISO 9001:2015 (and Annex A) in general though a few requirements have been combined and a few divided up for the sake of simplicity and easy usage. This complete manual contains 44 procedures – addressing each ISO 9001:2015 clause – including a procedure that makes it easy to establish your company’s quality objectives. All procedures have been designed from scratch to be true templates that – together with detailed customization instructions – allow you to create your own, individual ISO 9001 documentation, error-free and fully ISO 9001:2015 compliant. The two key features are:

Easy Implementation of ISO 9001: This pre-written template has been developed for easy ISO 9001 setup. The customization is very easy and fast if you follow the included detailed, step-by-step customization instructions.

Easy Compliance with ISO 9001: Your ISO 9001 documentation, which you will create using this template, will make it easy for your company to actually follow the requirements of ISO 9001 without unnecessary bureaucracy and paperwork.

14)Customization Instructions – ISO 9001 Procedures Manual

The “Customization Instructions – ISO 9001 Procedures Manual” are easy-to-understand and easy-to-follow, step-by-step instructions on how to edit the procedures templates to make them fit your company. Customization instructions have a major impact on the ease of customization and the quality of the final, customized documentation. We placed particular emphasis on the quality of our customization instructions to ensure that you will be able to develop excellent and individualized ISO 9001 documentation in the shortest amount of time

Step 3: ISO Implementation & Training

15)Work Instructions

Work instructions are the detailed, step-by-step instructions that are specific to your company’s individual work processes. Our All-In-One Easy 9001 Toolkit includes an easy to fill-in work instructions template, plus sample work instructions for the planning of new projects, products and services. Work instructions are typically written by the people performing the work; these two tools are designed to make it easy for them.

16)Set of 32 ISO 9001 Forms & Checklists

Our “Set of 32 ISO 9001 Forms & Checklists” make the ISO 9001 implementation and the compliance with ISO 9001:2015 requirements so much easier as each form or checklist allows you to meet one, two or several ISO 9001 requirements in one easy step. These forms and checklists compliment the ISO 9001 Procedures Manual and make it easy to meet its requirements. All forms and checklists are professionally designed for ease of use: they are self-explanatory and they “walk” the user through an entire process (for example, the corrective action process). Due to this special feature, our forms replace many work instructions. All forms are ready for use either as paper form or electronic form. Though our ISO 9001 forms and checklists can be customized if needed, all that’s really necessary is to enter your company name and logo.

Form 1: Archive Label

The “Archive Label” is used to identify file storage boxes and to easily meet the ISO 9001 requirements for record retention and record destruction. You will find this easy-to-use label to be a real time-saver. Designed to meet ISO 9001:2015, clause 7.5.3 requirements.

Form 2: Calibration Form

The “Calibration Form” is an important part of any calibration program. It includes calibration instructions and calibration records. The form can be easily used for a wide range of devices that require calibration. Designed to meet ISO 9001:2015, clause 7.1.3 and 7.1.5 requirements.

Form 3: Corporate Environment Form

The “Corporate Environment Form” is an important strategic planning tool that is used to define the internal and external environment in which the company operates. This form addresses several ISO 9001:2015 requirements related to the ‘context of the organization’ (ISO 9001:2015, clause 4.1 and 4.2).

Form 4: Corrective and Preventive Action Plan

Our “Corrective and Preventive Action Plan” form (short, “CAP”) walks the user through the entire corrective action process (or the entire preventive action process) – it is not necessary to refer to separate instructions. The corrective action process is a key ISO 9001 requirement; using our self-explanatory form makes meeting requirements of ISO 9001:2015, clauses 4.4, 6.1, 6.3, 8.5.6, 9.1.1, 10.1, 10.2 and 10.3 particularly easy.

Form 5: Customer Complaint Resolution

Resolving a customer complaint in a professional way can turn a disgruntled customer into a satisfied and loyal customer. Our “Customer Complaint Resolution” form ensures that no opportunity is missed to properly resolve every customer complaint. The form includes brief work instructions to ensure that all aspects of this important ISO 9001 requirement (ISO 9001:2015, clause 9.1.2) are met.

Form 6: Customer Survey

Finding out what your customers really think of your business is not only crucial if you want to stay ahead of your competition but it is also a central ISO 9001 requirement. Use our innovative “Customer Survey” form as a template for your company-specific survey that allows you to gain valuable customer feedback without taking much of your customers’ time. Designed to meet the requirements of ISO 9001:2015, clause 9.1.2.

Form 7: Employee Evaluation

The “Employee Evaluation” form is used for the periodic employee performance evaluation – but it is more than just a regular employee review: we included several sections to cover a spectrum of ISO 9001 requirements in one easy step. Our innovative “Employee Evaluation” form saves you much time and efforts during the ISO 9001 implementation and while meeting ISO 9001:2015, clause 7.2 and 7.3 requirements.

Form 8: Employment Checklist

Hiring a new employee usually requires various documents, related to government regulations, company policy etc. Use the “Employment Checklist” to make the employment process easy for the hiring manager, to ensure that consistently all required documents are in place for each new employee, and to meet ISO 9001:2015, clause 7.1.2, 7.2 and 7.3 requirements.

Form 9: Employment Termination Checklist

Many companies are increasingly afraid of firing employees due to the risk of lawsuits. Our “Employment Termination Checklist” is designed to minimize this risk as it includes a 15-point checklist that requires the firing manager to meet important requirements before terminating an employee. In addition, our “Employment Termination Checklist” includes a checklist used after an employee is terminated. Designed to meet requirements of ISO 9001:2015, clause 7.1.2, 7.2 and 7.3.

Form 10: Engineering Change Request

The “Engineering Change Request” (ECR) form is used to have engineering evaluate a concern or improvement suggestion. The “Engineering Change Request” form is comprehensive yet easy-to-use; it includes a section to describe the requested changes (including sketches), a section on effects on products and assemblies, a section for the evaluation and follow-up action. Using this form will save you time and prevent mistakes.

Form 11: Interested Parties Worksheet

The “Interested Parties Worksheet” is used to gather required information for the definition of the corporate environment during strategic planning. This user-friendly worksheet includes instructions for an easy way to meet the requirements of ISO 9001:2015, clause 4.2.

Form 12: ISO 9001 Management Review Form

The “ISO 9001 Management Review Form” is a particularly valuable form: it is used to keep a record of the ISO 9001 required Management Review Meetings, it includes the agenda points of the ISO 9001 Management Review Meetings, and it includes action plans that allow for easy follow-up. Using our “ISO 9001 Management Review Form” will allow you to meet several ISO 9001 requirements (ISO 9001:2015, clauses 9.1.3, 9.3.1, 9.3.2, 9.3.3, and 10.1); in addition, you will be able to avoid a typical ISO 9001 audit non-compliance.

Form 13: Job Description

Our comprehensive “Job Description” form allows you to easily meet various ISO 9001 requirements in one easy step. The form includes instructions that help filling out the form. Designed to meet ISO 9001:2015, clauses 5.3, 7.2 and 7.3 requirements.

Form 14: Maintenance Form

The “Maintenance Form” is an easy way to establish any kind of maintenance program (for example, equipment maintenance, maintaining work environment etc.). The form combines maintenance plan and maintenance records; instructions are included. This efficient form is designed to meet ISO 9001:2015, clauses 7.1.3 and 7.1.4 requirements.

Form 15: Meeting Notes Template

The “Meeting Notes Template” is designed to help you gain more benefits from any meetings. Use this simple form to not only keep meeting minutes but to end your meeting with a specific action plan.

Form 16: New Employee Training Plan

New employees typically require company-specific training and introduction to the company. The “New Employee Training Plan” is designed to consistently provide the needed training to new employees and keep a record of the training. Designed to meet ISO 9001:2015, clauses 7.2 and 7.3 requirements.

Form 17: On-The-Job Training Plan

Many companies that provide on-the-job training struggle with the ISO 9001 requirements that call for training plans and training records. Our “On-The-Job Training Plan” allows you to easily meet these important ISO 9001 requirements virtually within a few moments. Designed to meet ISO 9001:2015, clauses 7.2 and 7.3 requirements.

Form 18: Operational Planning Form

The “Operational Planning Form” is a 10-step checklist for the planning of new projects, products or services. This important ISO 9001 form makes it easy to meet the ISO 9001 requirements on operational planning and control (ISO 9001:2015, clause 8.1) – you don’t even need to refer to the “ISO 9001 Quality and Procedures Manual”.

Form 19: Opportunity Management Matrix

The “Opportunity Management Matrix” is an easy-to-use tool to manage opportunities that could benefit your company. The form enables you to easily generate a priority number, which will be used to identify opportunities that should be further pursued. This form includes instructions to make it easy to meet ISO 9001:2015, clauses 6.1 and 10.1 requirements.

Form 20: Pre-Employment Checklist

The “Pre-Employment Checklist” is designed to make your hiring process more consistent and avoid missing important steps during the employee selection and hiring process. Easily customize this checklist to meet the requirements specific to your company.

Form 21: Process Change Form

The “Process Change Form” is designed to guide the user step-by-step through the ISO 9001:2015 requirements for process change, including review and follow-up action. The form is easy-to-use and self-explanatory so you can easily meet the requirements of ISO 9001:2015, clauses 8.5.6.

Form 22: Process Definition Form

The “Process Definition Form” is a comprehensive form that addresses the numerous aspects of process management and simplifies compliance with the requirements of ISO 9001:2015, clause 4.4.

Form 23: QC Inspection Form

The “QC Inspection Form” is used for any type of quality control inspection during the production process or prior to release to the customer. The form includes inspection instructions, inspection criteria and checklist, and a section on handling QC-failed products. Designed to meet the requirements of ISO 9001:2015, clause 8.6.

Form 24: Receiving Inspection Form

The “Receiving Inspection Form” is an efficient tool to facilitate and document the inspection of received raw materials, parts, or other items that are crucial for the company’s production or service provision. The “Receiving Inspection Form” can easily be customized to include your specific inspection criteria, inspection method (100% inspection or sampling method). Designed to meet ISO 9001:2015, clauses 8.4 and 8.6 requirements.

Form 25: Record Retention Guide

ISO 9001 contains specific requirements for record retention. Our “Record Retention Guide” is a very valuable template enabling you to easily establish your company’s own record retention policy and make it available to all staff, thus easily meeting this key ISO 9001 requirement (ISO 9001:2015, clause 7.5).

Form 26: Risk Management Matrix

The “Risk Management Matrix” is an easy-to-use tool to manage risks that are potentially harmful to your company. The form enables you to quickly generate a priority number, which will be used to identify severe risks while filtering out unimportant risks that don’t need to be addressed. Designed to meet ISO 9001:2015, clauses 6.1 and 10.1 requirements.

Form 27: Supplier Disqualification Form

The “Supplier Disqualification Form” is used to handle problems with an established supplier and to eventually disqualify the supplier; the form also contains a section on re-qualification of the supplier. The form is self-explanatory, making it easy to meet the requirements of ISO 9001:2015, clause 8.4.

Form 28: Supplier Review Form

The “Supplier Review Form” is designed to make the selection of new suppliers more efficient and transparent. With this form, it is easy to focus on the most important features of any new supplier and compare several supplier candidates in order to identify the best choice. Designed to meet ISO 9001:2015, clause 8.4 requirements.

Form 29: SWOT Analysis Worksheet

The “SWOT Analysis Worksheet” is used to gather required information for the definition of the corporate environment during strategic planning. This user-friendly worksheet includes instructions to make it particularly easy to meet ISO 9001:2015, clauses 4.1 requirements.

Form 30: Training Evaluation Form

The “Training Evaluation Form” is designed to make your employees evaluate training sessions by focusing on the benefits to the company. Use this form to make your in-house training more efficient and to evaluate training providers. The “Training Evaluation Form” can be used to easily demonstrate compliance with several ISO 9001 requirements (ISO 9001:2015, clauses 7.2, 7.3, 8.4 and 9.1.3).

Form 31: Training Plan

This professionally designed “Training Plan” template allows you to not only meet the three ISO 9001 requirements for the planning of training, evaluation of training, and maintaining training records easily; it also requires considering the benefits to the company before actually approving a training request. The “Training Plan” has a double benefit: it allows you to easily meet key ISO 9001 requirements (ISO 9001:2015, clauses 7.2 and 7.3), and it potentially saves your company much unnecessary training expenses.

Form 32: Training Record Form

Our “Training Record Form” is not just a sign-in sheet to keep the ISO 9001 required training records. We designed the “Training Record Form” to focus on training objectives and potential follow-up training, in addition to easily establishing all ISO 9001 required training records (ISO 9001:2015, clause 7.2) in one easy step.

17)Customization Instructions – ISO 9001 Forms & Checklists

Most companies will find that our ISO 9001 forms and checklists will need very little customization. However, we prepared these simple “Customization Instructions – ISO 9001 Forms & Checklists” to give you guidance in case that your company’s circumstances require additional modifications.

18)Set of 10 Employee Newsletters

This “Set of 10 Employee Newsletters” is designed to educate all employees in ISO 9001, to keep them involved and to keep them aware of the company-wide ISO 9001 implementation effort. Employee acceptance and involvement is crucial for the success of ISO 9001, and this series of easy-to-read and eye-opening newsletters will make a great contribution.

Topics include updates on the ISO 9001 implementation project, changes to corporate procedures, ISO 9001 facts, flowcharting basics, document control tips, and much more.

19)PowerPoint Presentation “ISO 9001 for Everybody”

This professionally designed PowerPoint presentation is a great tool to keep employees and management involved in the ISO 9001 implementation and train them in important ISO 9001 issues. Topics of “ISO 9001 for Everybody” include: What is ISO 9001, Quality Management versus Quality Control, Process Approach, Documentation Requirements, Factors for Success, How to implement ISO 9001, Writing Instructions, and many more.

Step 4)Internal Audits

20)Internal Auditor Position Description

The “Internal Auditor Position Description” includes a description of job requirements, work environment and qualifications of your company’s internal ISO 9001 auditor. The purpose of this document is to advertise the internal ISO 9001 auditor position, select the ideal candidate, and document the requirements for the internal ISO 9001 auditor position.

21)Instructions for Internal ISO 9001 Audits

The “Instructions for Internal ISO 9001 Audits” will make auditing easy for your company’s internal auditor. These instructions, though concise, are a valuable guide loaded with details.

22)ISO 9001:2015 Audit Checklist

Your company’s internal ISO 9001 auditor will use the “ISO 9001:2015 Audit Checklist” as an invaluable and time-saving tool that makes any internal ISO 9001 audit as easy as possible. The audit checklist will not only guide the auditor through the entire ISO 9001 audit (using the process approach), but it is also used to accurately record all audit findings with direct references to the correct ISO 9001 requirements. A separate section of the “Checklist for Internal ISO 9001 Audits” is designed to make the audit of executive management as easy and painless as possible.

23)Audit Report Form

The “Audit Report Form” is used by the internal ISO 9001 auditor to document and communicate the findings of the internal audit. The form is professionally designed to be clear and easy to use while, at the same time, present the complete audit findings to company management in a professional manner.

Step 5) ISO 9001 Certification

24)Insider Secrets for a Successful ISO 9001 Certification Audit

Passing the ISO 9001 certification audit is the goal; access to insider information will make achieving this goal so much easier. Our “Insider Secrets for a Successful ISO 9001 Certification Audits” have been compiled over many years in working with numerous ISO 9001 auditors and registrars throughout the world. These secrets contain detailed audit preparation instructions that will be of invaluable help to you and your employees in preparing for a successful ISO 9001 certification audit. Especially the following chapters of our “Insider Secrets for a Successful ISO 9001 Certification Audit” are loaded with insider information.

25)Powerful Marketing of your ISO 9001 Certification

This concise guide will help you define a powerful marketing strategy in order to reap the full marketing benefits of your ISO 9001 certification: increased sales, increased market share and increased profits. Put the numerous tips and instructions of “Powerful Marketing of your ISO 9001 Certification” to work as soon as you passed your ISO 9001 certification audit, and start leveraging your ISO 9001 certification through successful marketing.

24. 24/7) Expert Customer Support

You are not alone during your ISO 9001 implementation! Our team of senior ISO 9001 experts is standing by to assist you with personal customer service throughout the entire ISO 9001 implementation project. Please contact us anytime 7 days a week, and you can expect a competent and detailed response that addresses all your questions.