Selecting the Right Powder-Type Wire Drawing Lubricant for Ferrous Wire (7 mm to 2 mm)

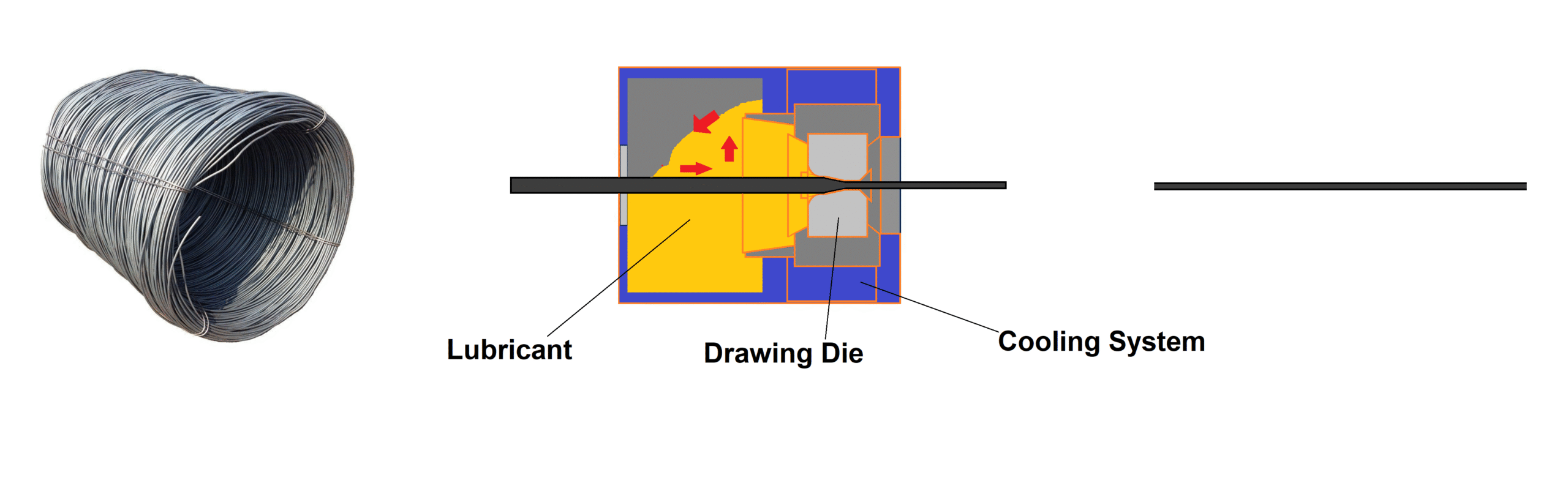

Selecting the optimal wire drawing lubricant for dry drawing of ferrous wire (reducing rod from about 7 mm down to 2 mm diameter) is crucial for efficiency, wire quality, and die life. In a typical multi-pass steel wire drawing process, the lubricant forms a protective film that minimizes friction between the wire and dies, thereby reducing wear and heat generation. An appropriate powder-type lubricant (also known as a wire drawing soap) can mean the difference between smooth operations with long die service life, or frequent breakdowns and poor-quality wire surface. This article, written in the voice of a technical consultant, explains how to choose the right dry drawing lubricant for medium-size ferrous wires, preserving technical depth and best practices while maintaining a clear, authoritative tone.

Understanding Dry (Powder-Type) Wire Drawing Lubricants

Key Factors in Selecting a Wire Drawing Lubricant

Best Practices for Using Dry Wire Drawing Lubricants

Supplier Insights: Leading Wire Drawing Lubricant Solutions

Conclusion

Understanding Dry (Powder-Type) Wire Drawing Lubricant

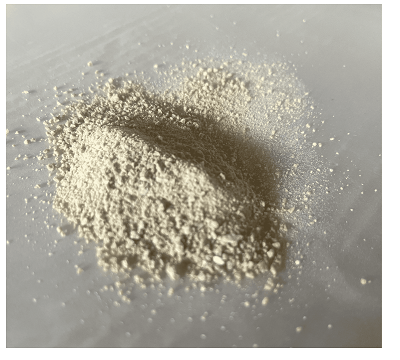

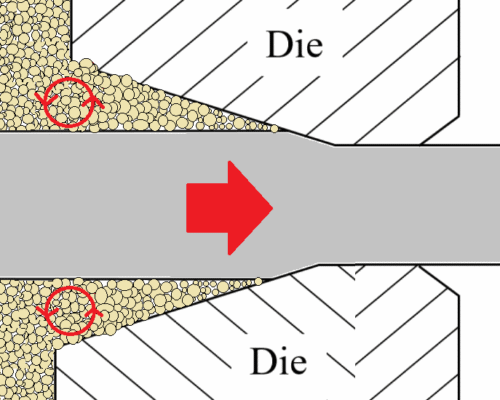

Dry drawing lubricants (often called wire-drawing soaps or powders) are usually mixtures of metallic soaps, fats, and solid additives designed to reduce friction in the die. The primary lubricating components are metal stearate soaps – most commonly calcium stearate and sodium stearate, or blends of these. A typical formulation for a ferrous wire drawing soap might include 15–20% calcium stearate, 10–15% aluminum stearate (a soap that can increase film strength), a large portion of hydrated lime (calcium hydroxide, 60–70%) as a solid carrier/filler, and a small amount of graphite (2–5%) for additional lubricity. The calcium or sodium stearate soap in the powder provides the primary lubricating film by melting or softening under friction; the lime acts as a porous binder that carries the soap and helps it coat the wire, while also keeping the lubricant film from becoming too fluid at high temperature. Graphite or other additives may serve as solid lubricants or extreme-pressure additives to further reduce friction and wear.

One key distinction is calcium vs. sodium-based lubricants. Calcium stearate is a “hard” soap with a moderate melting/softening point; it tends to form a sturdy, tenacious film that can withstand heavy reductions. Sodium stearate is a “soft” soap with a higher melting point and is water-soluble, which makes it easier to clean off the wire. Sodium soaps often provide a brighter wire surface and are particularly useful after certain pretreatments – for example, a sodium soap lubricant is especially effective when drawing phosphated steel wire, as it adheres well to the phosphate coating and can enhance lubricity after that process. In practice, many commercial dry lubricants are blends of calcium and sodium soaps, aiming to balance film strength and cleanability. Modern lubricant suppliers optimize properties like particle size distribution and softening point to suit specific applications – ensuring the powder melts into a lubricating film at the appropriate temperature for a given drawing speed and wire type. For instance, drawing a high-carbon spring wire at high speed may require a lubricant with a higher softening point (to resist being wiped away by heat), whereas a slower draw of mild steel might use a lower softening point for better film formation.

Besides soaps and lime, specialized additives are used in some lubricants to address specific challenges. For demanding applications (e.g. high tensile wire or large diameter rod), lubricants might include extreme pressure (EP) additives to further reduce die wear, or solid lubricants like graphite or molybdenum disulfide (MoS₂) to enhance lubricity under high load. Waxes or polymer additives can improve film consistency and corrosion protection of the drawn wire. Each formulation tweak – whether it’s adding graphite for additional lubricity or modifying the soap ratio – is intended to improve performance for a certain range of wire sizes, materials, and drawing conditions.

Key Factors in Selecting a Wire Drawing Lubricant

Choosing the right powder-type wire drawing lubricant for reducing 7 mm steel rod to 2 mm wire involves evaluating several factors specific to your process and material. A knowledgeable consultant will typically consider the following criteria when making a recommendation:

-

Wire Material and Metallurgy: The composition and tensile strength of the steel influence lubricant choice. Low-carbon steel (mild steel) is relatively soft and may not require as “heavy-duty” a lubricant as high-carbon or alloy steel. High-carbon wires (e.g. spring wire, music wire) generate higher drawing forces and heat, benefiting from higher-fat or specialty lubricants with solid additives for extra friction reduction. If the steel is hard or heat-treated, the lubricant must provide robust film strength to avoid scoring the wire surface.

-

Surface Preparation (Coatings): Examine how the wire rod is prepared before drawing. Ferrous wire is often pretreated either by phosphate coating or by a lime (alkaline) wash, especially for larger sizes. Phosphate coatings (typically zinc phosphate) create a rough, absorptive layer on the wire that acts as an excellent carrier for lubricants and can prevent metal-to-metal contact under extreme pressure. Wires drawn after phosphate coating usually use a sodium-based soap, since sodium soaps fill the porous phosphate layer well and can be drawn to fine sizes with reduced friction. Alternatively, some processes use a lime coating: dipping the cleaned rod in a hot lime solution, drying and baking it so that a thin layer of lime adheres to the wire. This lime particle layer helps the powder lubricant stick and form a consistent film during drawing, especially in the early dies. If your wire is mechanically descaled (no chemical coating), it will have a relatively smooth surface, so you’ll need a lubricant with excellent adherence to avoid lubricant “skipping” on the wire’s surface. In such cases, high-adherence formulations (sometimes with special tackifiers or a higher percentage of calcium soap) are recommended to ensure the powder continuously coats the wire.

-

Drawing Speed and Reduction Severity: The faster the drawing speed and the larger the total reduction, the more heat is generated. High-speed multi-die machines will heat the wire and dies more, so the lubricant must not break down at elevated temperature. Lubricants differ in their softening/melting point; a high-speed operation may require a higher softening-point lubricant that stays effective without burning off. Conversely, for slower or lighter reductions, a lower softening point can help the lubricant form a film more readily. The drafting practice (how much reduction is taken per pass and the number of passes from 7 mm to 2 mm) also matters. Heavy first-pass reductions typically call for a robust lubricant (often calcium-rich) to handle the load, whereas the final passes (smaller reductions) might switch to a softer or finer soap for surface finish. Indeed, it is common to use different lubricants in sequence: a high-performance calcium-based lubricant in the early passes for strong film and high pressure tolerance, and a sodium-based lubricant in the final one or two passes to improve surface finish and aid cleaning. Many wire drawers adopt this strategy to get the best of both worlds in a single drawing line.

-

Downstream Process Requirements: Consider what happens to the wire after drawing. If the drawn wire will be electroplated or coated (e.g. copper-plated welding wire, galvanized, etc.), the lubricant should be easy to remove. In such cases, finishing with a sodium soap is advisable because any residual sodium stearate can be washed off with hot water or mild alkaline cleaners, whereas calcium stearate is less water-soluble. As one industry guideline notes, “if the wire needs to be carefully cleaned after drawing for electro-plating or coppering then a water soluble sodium soap should be used at least in the final passes.This ensures minimal interference with the plating adhesion. On the other hand, if the wire’s next step is something like batch annealing or heading (as for making bolts, screws, etc.), a calcium-based soap might be preferred for its lubricity during that post-drawing process (some residue can actually protect the wire surface in annealing or forming). Always match the lubricant to the end-use: for example, welding wires often require lubricants that don’t leave excessive residue, to ensure clean copper plating and good electrical performance, whereas spring wires or tire cord wires prioritize lubricity and consistent coating because they undergo further twisting or forming.

-

Die Design and Equipment Constraints: Modern drawing machines and dies also influence lubricant choice. Some machines have provisions for heating or cooling the dies, others may have constrained die box sizes or specific lubricant feeding systems. A lubricant must flow freely in the soap box and continuously coat the wire. If the powder cakes up or bridges, it can result in lubricant starvation and wire breakage. For instance, coarse, granular lubricants might not feed well in certain small die boxes, whereas a finer or pelletized form might. Equipment with straight-line wire paths might retain lubricant differently than machines with rotating capstans, so the consultant considers how well a given lubricant adheres to the wire under those mechanics. Also, if the machine has high-capacity dust filtration or collection, dust generation of the lubricant might be less of an issue; but if not, a low-dusting lubricant would be important for maintenance and operator safety.

-

Environmental, Health, and Cost Considerations: It’s increasingly important to factor in the health and safety profile of the lubricant. Traditional wire-drawing soaps sometimes included additives like borax (sodium borate) to improve performance; however, borax is now restricted in the EU due to health concerns. Top suppliers have reformulated to provide borax-free lubricants without sacrificing performance. For example, Traxit International moved to completely borax-free production of dry lubricants, replacing borax with alternative additives and often using sodium-based formulas, by 2010. Dust is another concern: fine powder lubricants can create airborne particles in the plant, posing inhalation and dust explosion hazards. Modern lubricants aim to minimize dust generation, through both formula adjustments and offering the lubricant in pelletized or “beaded” forms. Pellet or micro-granulated lubricants are easier to handle with less dust compared to traditional fine powders. Additionally, the cost and consumption rate of the lubricant matter to any operation. Some high-performance soaps might be more expensive per kilogram, but if they allow faster drawing speeds, lower consumption per ton of wire, or longer die life, they can be cost-effective overall. Many new formulations tout benefits like reduced soap consumption and easier cleaning (hence lower waste treatment costs) – all of which can factor into the selection decision for a cost-conscious buyer.

By weighing all these factors – wire type, surface prep, drawing conditions, downstream needs, equipment, and EHS/cost considerations – a technical consultant can narrow down the field of candidate lubricants to those best suited for the specific ferrous wire drawing scenario.

Best Practices for Using Dry Wire Drawing Lubricant

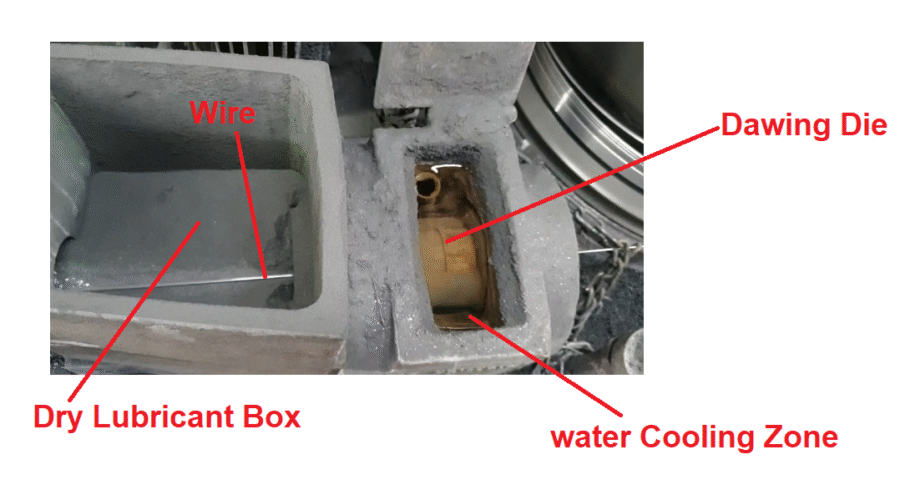

Selecting a good lubricant is only part of the equation; proper usage and maintenance practices ensure you get the best performance from that lubricant. Here are several best practices to follow once you’ve chosen a powder-type wire drawing lubricant:

-

Maintain Proper Wire Pre-Coating: Ensure the wire rod is adequately cleaned and (if applicable) coated before it enters the draw. If you rely on a lime coating, maintain the correct coating weight – too little lime and the lubricant won’t adhere well; too much and it might flake. For phosphate coatings, monitor the coating process so that the layer can hold the lubricant (phosphate quality can degrade with bath contamination over time). A consistent pre-coat leads to consistent lubricant pick-up in the first die.

-

Optimize Die Box Setup: Fill the lubricant soap boxes to the recommended level and keep them covered if possible (to prevent contamination and moisture pickup). The lubricant should flow freely around the wire; avoid packing the powder too tightly into the box, as it needs to circulate and coat the wire continuously. Some plants use mechanical stirrers or vibrators on larger soap boxes to prevent the powder from compacting, especially for fine powders. Also, ensure the entry of the wire into the box and die is aligned so the wire actually passes through the lubricant media evenly – misalignment can cause one side of the wire to starve of lubricant.

-

Monitor Lubricant Condition and Feed: Over time, debris such as mill scale or metal fines from the wire can accumulate in the lubricant. Implement a schedule to sieve or refresh the lubricant in the boxes periodically to remove contaminants. cKeep an eye on lubricant consumption per ton of wire; a sudden drop in consumption might indicate insufficient lubricant pickup (perhaps due to caking or humidity issues). Most modern dry lubricants are formulated to resist caking, but high humidity or long downtime can still cause clumping – if you suspect this, empty and replace the powder and store the lubricant in a dry area. Avoid mixing different lubricants in the same box unless recommended (e.g. when transitioning from one soap to another in later passes), because incompatible chemistries could lead to performance issues like hard residues.

-

Control Drawing Temperatures: Excessive heat is the enemy of lubrication. If the dies run too hot (due to machine issues or overly aggressive speeds), even the best lubricant can degrade. Make sure die cooling systems (if any) are functioning. A useful guideline is that die temperature should not exceed the lubricant’s melting point by too much – if it does, the lubricant film may become too thin or burn. If you notice smoke or burnt soap odor, it’s a sign the lubricant is being pushed beyond its thermal limit, and you may need to adjust the process (slower speed, better cooling, or a higher-temperature lubricant).

-

Safety and Housekeeping: Even with low-dust formulations, some powder will escape into the environment around the machine. Maintain good ventilation or local exhaust near drawing machines. Regularly clean up spilled or settled lubricant (but do so gently to avoid kicking up dust; vacuum systems with proper filters are preferable to sweeping). Besides general cleanliness, this is important to prevent any risk of dust fires or explosions; dry lubricant powders are organic and can be combustible when dispersed in air. Follow supplier data on the flash point or any dust explosion class of the product, and ensure any electrical enclosures or motors near the drawing line are dust-tight to avoid ignition sources. Operators should use appropriate PPE like dust masks or respirators if needed when handling the powder directly.

-

Evaluate Performance and Iterate: Implement a practice of monitoring key performance indicators (KPIs) such as wire surface quality, die life (number of kilograms per die), wire breaks, and soap consumption as you use a given lubricant. These metrics will tell you if the lubricant is performing as expected. For instance, if you switched to a new “low-friction” lubricant and you see die life improve by 20%, that’s a good validation. If you try a different finishing soap for easier cleaning and notice your downstream plating rejection rate goes down, that’s a successful trial. Conversely, if issues arise (e.g., more wire breaks or a dusty environment), consult with the lubricant supplier’s technical support – they can often adjust the recommendation (perhaps a slightly different grade from their range) to better suit your particular drawing line. The goal is continuous optimization: the right lubricant, used correctly, will consistently produce good wire at high efficiency.

Supplier Insights: Leading Wire Drawing Lubricant Solutions

Below is a list of 10 established global manufacturers that provide dry (powder-type) lubricants for ferrous wire drawing (ideal for reducing steel wire diameters from ~7 mm down to ~2 mm). Each entry includes the company name, country/region, notable dry lubricant product line, a brief overview, and an official website reference.

-

Traxit International (Germany) – One of the world’s largest wire drawing lubricant producers, offering over 450 high-grade lubricants (including many dry drawing soaps) for steel, stainless, and non-ferrous wires. With ~140 years of experience in wire lubrication, Traxit provides a comprehensive range of dry drawing powders and coating agents tailored to maximize drawing speed, die life, and wire surface quality. (Now part of Klüber/Freudenberg Group.)

-

Condat S.A. (France) – A world leader in wire-drawing lubricants, known for its VICAFIL and STEELSKIN dry drawing soap product lines. Condat’s Vicafil powders (calcium- or sodium-based soaps) cover virtually all cold drawing applications and are internationally recognized in the ferrous wire industry. The premium Steelskin range is formulated for the most demanding draws, incorporating additives (graphite, MoS₂, waxes, etc.) to reduce die wear and friction in high-stress reductions.

-

Aztech Lubricants (USA) – A global supplier of wire drawing lubricant technologies, offering the EZDraw™ series of dry drawing powders alongside oils, vanishing lubricants, precoats (EZCoat™), and cleaners. Aztech’s dry lubes are typically calcium, sodium, or potassium stearate-based powders engineered for high lubricity and low residue. Founded in 2005, Aztech now manufactures in the US, Colombia, India, and Korea, providing custom-blended solutions to improve drawing performance and safety.

-

H.L. Blachford Ltd. (Canada/USA) – A North American manufacturer supplying world-class wire drawing lubricants to over 20 countries on 5 continents. Blachford produces a full range of low-dust dry drawing soaps (both sodium- and calcium-based) under proprietary brands like Chemdraw® and Caplube®, designed for critical applications such as welding wire, tire bead/cord, spring wire, etc. These lubricants yield significantly lower dust, reduced consumption, higher drawing speeds, and longer die life in high-carbon wire drawing. (Blachford also offers wet lubricants, greases, and precoating compounds for ferrous and non-ferrous drawing.)

-

Lubrimetal S.p.A. (Italy) – An Italian manufacturer (founded 1959) specializing in lubricants and chemicals for wire drawing and metal surface treatment. Lubrimetal’s flagship LUBRIFIL® product line consists of dry drawing lubricants – high-performance powder soaps available in calcium-based, sodium-based, mixed, and borax-free formulations. These dry lubes are used worldwide for drawing of ferrous wires (high/low carbon steel, stainless, etc.). Lubrimetal also produces wet drawing fluids (LUBRIOL® oils/emulsions), phosphate coatings (FOSFIL®), and polymer-based lubricant carriers (STEELFOR®) to support the wire industry.

-

Pan Chemicals S.p.A. (Italy) – An Italian company (est. 1987) producing high-tech wire drawing lubricants, coatings, and auxiliary chemicals, with worldwide sales via branches and agents. Pan’s dry lubricants are sold under the PANLUBE S series – a complete range of calcium, sodium, aluminum, zinc, lithium and combined soap powders suitable for drawing low- and high-carbon steel as well as stainless steel. They also offer PANLUBE L wet lubricants (oils, greases for wire drawing), PANCOVER lubricant carriers (reactive/non-reactive coatings like phosphates), plus galvanizing fluxes and other process aids.

-

BASF (Chemetall) (Germany) – BASF’s Chemetall division supplies the Gardolube® family of lubricants and coating agents for wire drawing and cold forming. Gardolube is a well-known trademark for high-efficiency drawing soaps and salt carriers that have become a global standard in high-quality wire and tube drawing processes. This product portfolio includes reactive soap powders (stearate-based lubricants that bond to phosphate-coated wire) and non-reactive lubricants, all designed to reduce friction and extend die life in ferrous wire drawing.

-

Kyoeisha Chemical Co. (Japan) – A leading Japanese manufacturer of metalworking chemicals, known for its KOSHIN brand of wire drawing lubricants. Kyoeisha’s KOSHIN dry lubricants hold the highest market share in Japan and are widely used for ferrous wire drawing – from low-carbon wires (e.g. galvanized wire, nails) to high-carbon applications like bead wire and steel cord. Their dry product range includes various powder soaps (e.g. KOSHIN H- series, S- series) formulated for different wire materials and pretreatments (lime-coated, phosphated, etc.), as well as complementary wet lubricants for fine wire drawing.

-

HOLIFA Lubricants (Germany) – A German company (based in South Westphalia) with over 60 years of experience in metal-forming lubricants for the wire industry. HOLIFA offers a complete range of drawing powders covering all common soap types. Its HOLIFA EZ and B400 series (calcium-stearate based powders) and HOLIFA CO series (sodium-stearate powders) are known and highly regarded worldwide. They also provide mixed soap formulations (PF series, combining calcium and sodium benefits so one powder can be used throughout a multi-die process) and even synthetic specialty powders (HOLIFA W series) for cases where standard soaps are insufficient.

-

Henkel AG (BONDERITE®) (Germany) – Henkel, through its Bonderite product line, supplies advanced dry lubricants and coatings for ferrous wire drawing as part of its cold-forming solutions. This includes reactive lubricants (high-purity stearate soap powders that chemically bond to phosphate-treated wire surfaces, providing strong lubrication films) as well as non-reactive polymer-based dry coatings for wire drawing. These Bonderite dry lubricants (e.g. the L-FM series) aim to minimize metal-to-metal contact, reduce friction, and improve die life and wire surface quality in drawing operations. (Henkel’s one-step polymer coating BONDERITE L-FM FL is an example of a modern borax-free lubricant for wire drawing.)

Conclusion

Selecting the right powder-type wire drawing lubricant for drawing ferrous wire from 7 mm to 2 mm is a multi-faceted decision that balances chemistry and engineering. A subject-matter expert or consultant will maintain focus on the wire’s material characteristics, the drawing process parameters, and downstream requirements to narrow down the ideal lubricant options. The goal is to choose a wire drawing lubricant that provides consistent lubrication through each die pass – from the first heavy reduction to the final sizing – while protecting the wire’s surface and maximizing die life. Modern advancements by leading suppliers have expanded the choices available, from low-dust and borax-free soaps to tailor-made additive packages for extreme conditions. Technical buyers are encouraged to leverage these advancements: for instance, using a dual-lubricant strategy (calcium-rich followed by sodium-based) to marry strength with cleanability, or adopting a new-generation lubricant that allows higher speed without sacrificing wire finish.

Ultimately, the “right” lubricant is one that integrates seamlessly into your wire drawing operation and enhances it. If you maintain good practices (proper pre-coating, machine setup, and lubricant management) and collaborate with lubricant suppliers for support, you can achieve significant improvements in productivity and product quality. A well-chosen lubricant reduces friction and wear, thereby not only cutting costs (through longer die life and fewer rejects) but also enabling smoother downstream processing of the wire. In the highly competitive field of wire manufacturing, such gains are invaluable. By staying informed about lubricant technologies and choosing carefully, manufacturers can ensure their ferrous wire drawing lines run efficiently, safely, and yield a product that meets the highest standards of quality – all thanks to that unassuming but critical ingredient: the right wire drawing lubricant.

We also recommend that you Read This Article for more information on this topic.