Know-How

Know-how is knowledge of the methods or techniques of doing something, especially something technical or practical. Because many variables are involved in the production process of sensitive products such as welding consumables.It is necessary to take a completely systematic approach in the process of these products.We will fully classify this process by our experts and will help you to achieve the highest quality.

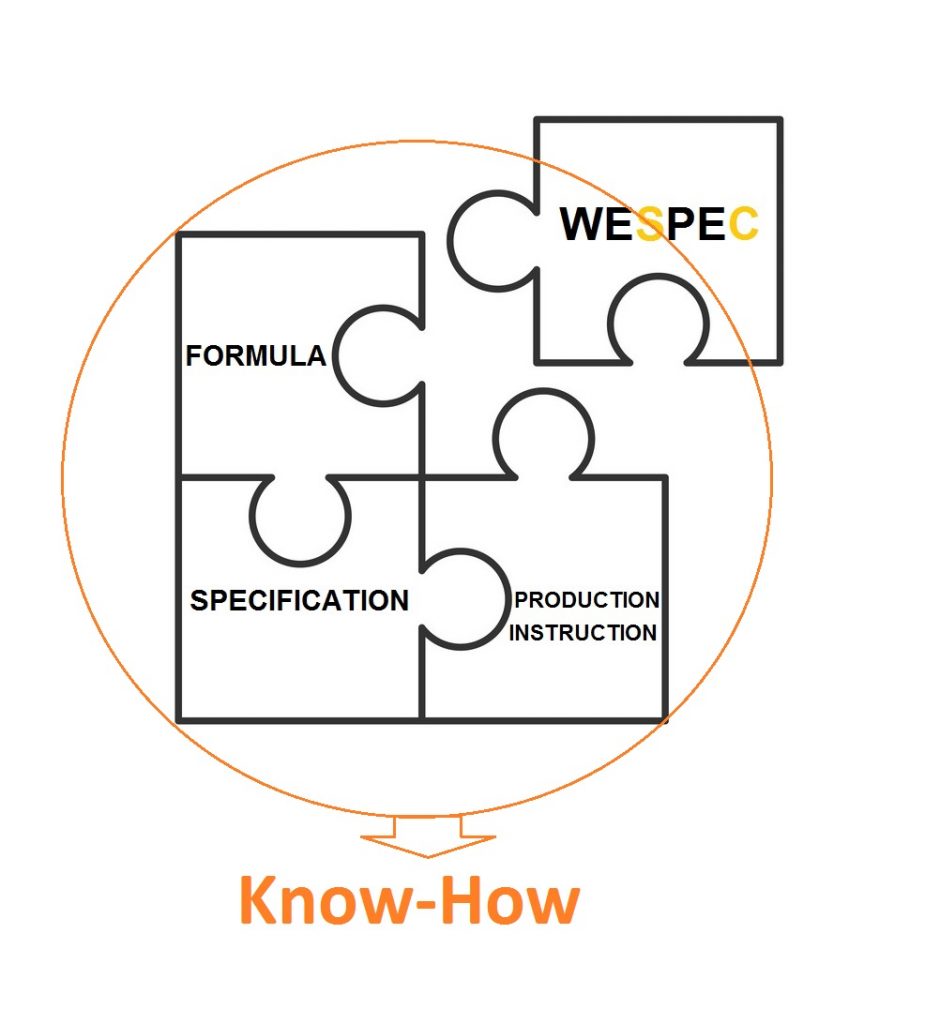

Wespec Belives that quality product will reach by solve this puzzle

know-how Includes the Following:

A- Formulas of components for manufacturing welding consumables.

B- Specification of raw material components, used in the formula.

C- Detailed description of the production instruction for all products.

A- Formulas:

1- Formulas for Covered Electrodes (Single & Double Coated).(see more)

2- Formulas for Submerged Arc Welding Flux.(see more)

3- Formulas for Flux Cored Arc Welding.(see more)

B- Specification of Raw Materials:

Each product has its own production formulation. also each raw material at this formula has its own spec sheet.For example, welding electrodes include three types of raw materials:

1- Wire : The exact specifications of the wire required include chemical analysis and the maximum, minimum, typical values of each element of the wire are shown in spec sheet.(see more)

2-Powder : Each electrode can contain an average, 10 to 20 types of mineral, chemical, metal, and ferroalloy. The specification sheet of each powder contains detailed properties of the powder, including chemical analysis, sieve analysis, density, humidity ,etc.(see more)

3- Binder : The main task of binder is to paste the required powder coating on the wire surface. This group of materials is mainly from sodium and potassium silicate compounds. The specification sheet of the raw materials contains precise properties including chemical analysis, density, viscosity, molar ratio and Baume.(see more)

C- Production Instruction:

Manufacture of single and double coated covered electrodes as per equivalent standards.(SMAW)(see more)

Manufacture of submerged arc welding fluxes as per equivalent standards.(SAW FLUX)(see more)

Manufacture of submerged arc welding Wires as per equivalent standards.(SAW WIRE)(see more)

Manufacture of flux cored arc welding wires as per equivalent standards.(FCAW)(see more)

Manufacture of gas metal arc welding wires and gas tungsten arc welding wire as per equivalent standards.(GMAW) (see more) (see more)