E71T-1 Production know-how: Formulation, Process

If you plan to produce E71T-1 flux-cored welding wire or your current product isn’t meeting quality targets,E71T-1 Production know-how package is for you. We cover the key raw materials used in E71T-1 and explain how each one affects weld quality, with practical points manufacturers must watch. For a complete E71T-1 production Know-How Package, contact us. We’ll support you from initial setup through to stable, high-quality output.

Introduction to E71T-1 Flux Cored Welding Wire

Raw Materials of E71T-1 Flux Cored Welding Wire

Production of E71T-1 Flux Cored Welding Wire

Why Proven E71T-1 Production Know-How Matters

Introduction to E71T-1 Flux Cored Welding Wire

E71T-1 is a rutile flux-cored carbon steel welding wire designed for high-productivity fabrication of mild and some low-alloy steels. Classified under AWS A5.20, it delivers ~70 ksi class strength with a smooth, stable arc, easy slag removal, and excellent weld bead appearance. It’s typically run on DCEP with external shielding—either 100% CO₂ (E71T-1C) or Ar/CO₂ mixes (E71T-1M)—and supports all positions (not vertical-down), making it a go-to choice for structural steel, shipbuilding, and heavy equipment work. Compared to solid wire, E71T-1 offers higher deposition rates and better tolerance to mill scale, helping reduce prep time on multi-pass welds while maintaining good impact toughness. For best results, control heat input, stickout, and travel speed; keep wire and gas dry and clean; and follow recommended parameters to minimize spatter and fume.

Raw Materials of E71T-1 Flux Cored Welding Wire

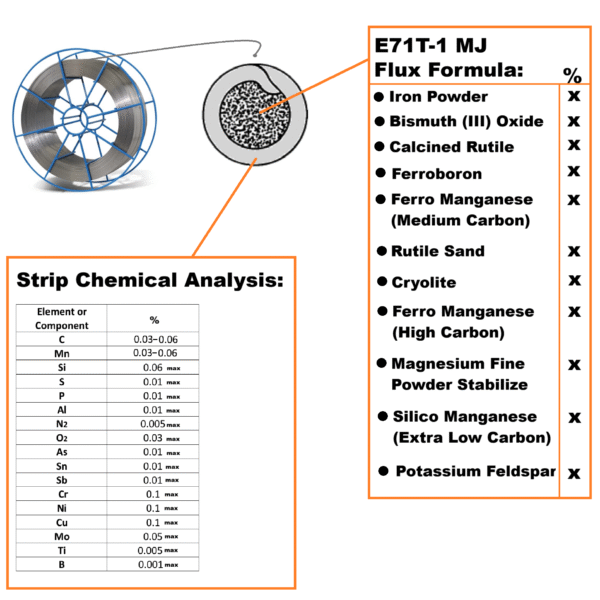

E71T-1 flux-cored welding wire is made from two material streams: (1) a low-carbon steel strip formed into a U-shape and closed to create the tubular sheath, and (2) a precisely weighed blend of mineral and metallic powders (the flux) placed inside that sheath according to a defined formulation.

The image shows the powdered flux constituents used in E71T-1 flux-cored welding wire, along with the chemical analysis of the steel strip (belt). Below, we describe the metallurgical function of each ingredient and how it influences arc behavior, slag action, bead shape, and the final weld properties.

Iron Powder

Metallurgical role: Adds metallic Fe to raise metal recovery and deposition efficiency; slightly dilutes oxygen picked up from the slag; supports formation of fine Ti-oxide inclusions (from rutile) that later act as acicular-ferrite nucleants.

In welding: Higher deposition rate, fuller beads, good tie-in. Too much increases spatter risk and can starve the slag (low slag/metal ratio → poor coverage and harder slag peel).

Bismuth(III) Oxide (Bi₂O₃)

Metallurgical role: Forms low-melting, fluid oxides with SiO₂/TiO₂/Al₂O₃; very minor Bi pickup in weld metal (kept very low).

In welding: Powerful wetting and slag-fluidity promoter → smooth bead face, easy slag detach, especially out-of-position. Overuse can make slag overly runny and reduce puddle support on vertical/uphill.

Calcined Rutile (TiO₂)

Metallurgical role: Principal slag former and arc stabilizer. Supplies Ti for stable Ti-oxide inclusions that refine microstructure and aid toughness; contributes controlled oxygen to the weld metal (needed for inclusion population but must be limited).

In welding: Soft, stable arc, excellent puddle control and easy re-ignition; fast-freezing, glassy slag gives all-position operability and nice bead appearance. Excess TiO₂ raises weld-metal O → more inclusions, potential toughness loss.

Ferroboron

Metallurgical role: Trace B micro-alloying (ppm level) improves hardenability and can promote acicular ferrite when balanced with O, Ti, and Mn; binds with N as BN, reducing grain-boundary nitrides.

In welding: Small additions can lift strength without sacrificing toughness. Overdose (or poor O/N control) increases hot-crack susceptibility and reduces impact toughness.

Ferro-Manganese (Medium-Carbon)

Metallurgical role: Strong deoxidizer; adds Mn to the weld metal (solid-solution strengthening and sulfide control as MnS). Medium-C grade lets you trim weld C to spec while supplying Mn.

In welding: Cleaner metal (lower O), better toughness, reduced porosity. Too much Mn raises strength but can depress CVN toughness and raise crack sensitivity in high-restraint joints.

Rutile Sand (additional TiO₂ source)

Metallurgical role: Complements calcined rutile to tune basicity/acidicity and viscosity; sustains the Ti-oxide inclusion population.

In welding: Helps maintain the classic “rutile arc feel.” Over-addition has the same oxygen/toughness trade-off noted above.

Cryolite (Na₃AlF₆)

Metallurgical role: Fluoride flux that lowers slag melting point and viscosity, dissolves refractory oxides (Al₂O₃, SiO₂), and assists hydrogen control by promoting dry, fluid slag.

In welding: Easier out-of-position work, crisp slag detach. Too much can make the slag too fluid (puddle wash-out on vertical) and increase fume.

Ferro-Manganese (High-Carbon)

Metallurgical role: Deoxidizer plus a controlled C addition when a slight weld-metal C lift is needed for strength/penetration; still supplies Mn for toughness and S control.

In welding: Hotter arc feel and deeper penetration. Must be balanced to keep weld C within E71T-1 chemistry for impact toughness.

Magnesium Fine Powder (stabilized)

Metallurgical role: Very potent deoxidizer/desulfurizer (forms MgO/MgS); trace Mg promotes fine oxide inclusion populations that can nucleate acicular ferrite; can scavenge O at the metal–slag interface.

In welding: Arc stabilization and porosity resistance. Over-addition risks violent reactions (spatter) and excessive inclusion volume → toughness penalty; hence the “stabilized” grade and low dosage.

Silico-Manganese (Extra-Low Carbon)

Metallurgical role: Primary Si + Mn deoxidizer package with minimal C pickup. Si ties up O as SiO₂ (goes to slag); Mn strengthens weld metal and fixes S as MnS.

In welding: Cleaner metal, less porosity, stable arc. Too much Si increases weld-metal oxygen equivalents and may lower CVN if inclusions grow/coarsen.

Potassium Feldspar (KAlSi₃O₈)

Metallurgical role: Supplies K (easily ionized) to increase arc conductivity/ionization, plus SiO₂/Al₂O₃ to the slag network.

In welding: Very stable arc starts and re-ignitions—important with CO₂ or Ar/CO₂ shielding; improves bead smoothness. Excess raises slag viscosity and can trap slag on toes if overdosed.

Production of E71T-1 Flux Cored Welding Wire

Seamed flux-cored welding electrode (e.g., E71T-1) is manufactured by slitting a low-carbon steel strip, cleaning it, and cold-forming it into a U-channel, then dosing a dried, sieved flux blend into the channel before closing the seam with forming rolls to create a tight, lock-seam tube. The filled wire is sized and compacted to the target fill ratio, annealed if required, drawn to final diameter, optionally copper-coated, and spooled. Throughout, moisture control (pre-dried flux, low-humidity handling), seam integrity (no leaks), and dimensional stability (OD, ovality, fill factor) are monitored. Final QC verifies chemistry (strip and flux), diffusible H₂, mechanicals (Rm, Re, CVN), operating behavior (arc stability, slag detach), and weld soundness per the E71T-1 classification.For more information, Read This Article that explains the production stages in detail.

Why Proven E71T-1 Production Know-How Matters

If you manufacture flux-cored welding wire—or plan to launch a line—you will invest heavily in facilities, machinery, and skilled staff. Without a repeatable, high-quality product, that investment is at risk. Purchasing, producing, and testing to validated know-how is the difference between costly trial-and-error and a stable, profitable operation. Read here a sample of Know-How on Flux Cored Welding Wire production.

What our E71T-1 Know-How Covers:

-

Powder Raw Materials

Detailed specifications for each ingredient, including chemical analysis, particle size distribution, moisture and LOI limits, functional role in the weld, and a vetted list of reputable suppliers. -

Steel Strip (Belt)

Target chemical analysis and allowable ranges, metallurgical and physical requirements, surface quality and cleanliness criteria, and approved grades and mills. -

Confidential Flux Formulation

Exact weight percentages and dosing ranges for every component, with fill-factor targets and guidance to maintain toughness, arc stability, and easy slag removal. -

Production Instructions

Step-by-step procedures for mixing and drying, forming and filling, compaction, drawing, copper coating, and spooling. Includes environmental controls, seam integrity checks, and in-process quality gates. -

Testing and Quality Control

Practical QC and certification plans for incoming materials and finished wire: sieve analysis, moisture and LOI, OD and ovality, cast and helix, coating weight, weld metal chemistry, tensile and yield, CVN impact, diffusible hydrogen, operability in CO₂ and Ar/CO₂, and acceptance criteria aligned with leading international standards.