E6013 Welding Electrode , A Buyer’s Guide

What is E6013 Welding Electrode

Characteristics of E6013 Welding Electrode

Suitable Welding Currents for E6013 Welding Electrode

Type of Current

Suitable Welding Position

Suitable Welding Equipment

Proper Packaging of E6013

Key Consideration for Buyers

Conclusion

Introduction

Welding is an essential process in many industries, from construction to manufacturing, and selecting the right welding electrode is crucial for achieving high-quality welds. Among the various options available, E6013 welding electrodes are particularly popular due to their versatility and ease of use. If you’re considering purchasing E6013 welding electrodes, this guide will help you understand their characteristics, benefits, and applications, ensuring you make an informed decision.

What is E6013 Welding Electrode

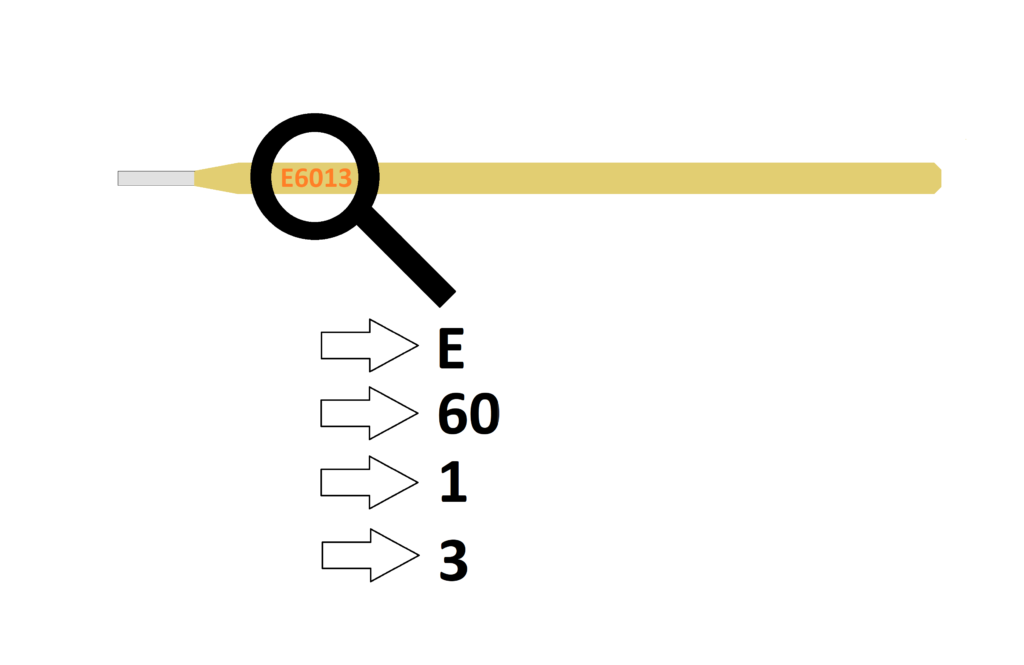

E6013 welding electrodes are a type of consumable rod used in the Shielded Metal Arc Welding (SMAW) process, also known as stick welding. The designation “E6013” provides essential information about the electrode:

– E stands for electrode.

– 60 indicates the minimum tensile strength of the weld metal, which is 60,000 psi.

– 1 signifies the electrode can be used in all welding positions (flat, horizontal, vertical, and overhead).

– 3 denotes the type of coating on the electrode and the current used (AC or DC).

Characteristics of E6013 Electrode

1.Versatility: E6013 electrodes are suitable for a wide range of welding applications, including both ferrous metals and mild steel. They are ideal for welding thin sheets and small diameter pipes.

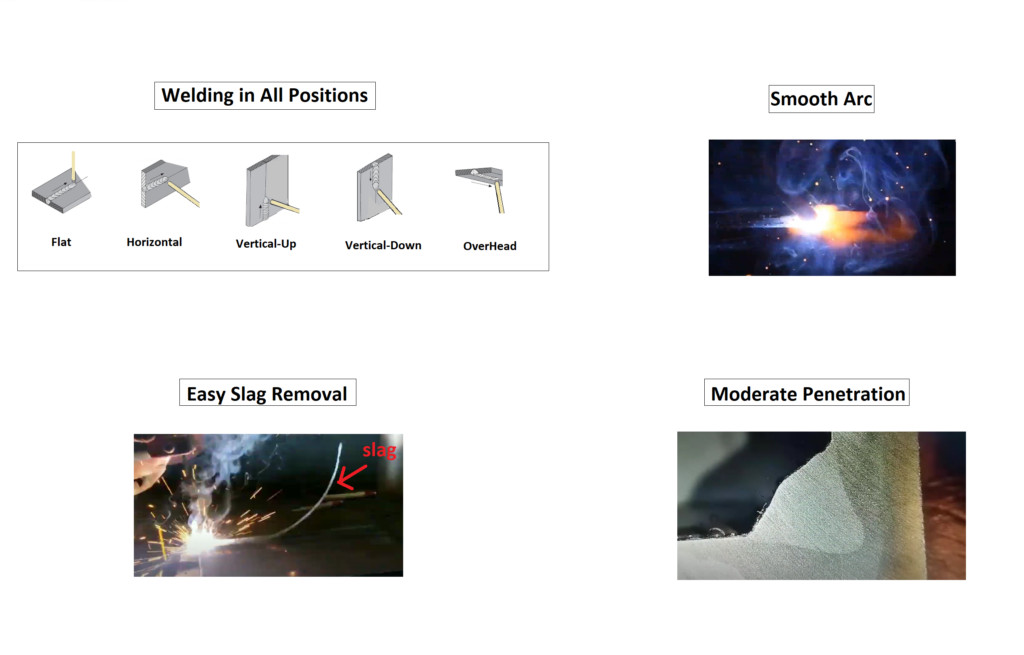

2. All-Position Welding: These electrodes are designed for welding in all positions, making them highly versatile for various welding tasks.

3. Smooth Arc Action: E6013 electrodes provide a stable and smooth arc, which helps in creating clean and aesthetically pleasing welds. This characteristic is particularly beneficial for beginners.

4. Easy Slag Removal: The slag formed during welding with E6013 electrodes is relatively easy to remove, which simplifies post-weld cleanup and inspection.

5. Moderate Penetration: These electrodes offer moderate penetration, making them suitable for welding thin to medium-thickness materials without burning through.

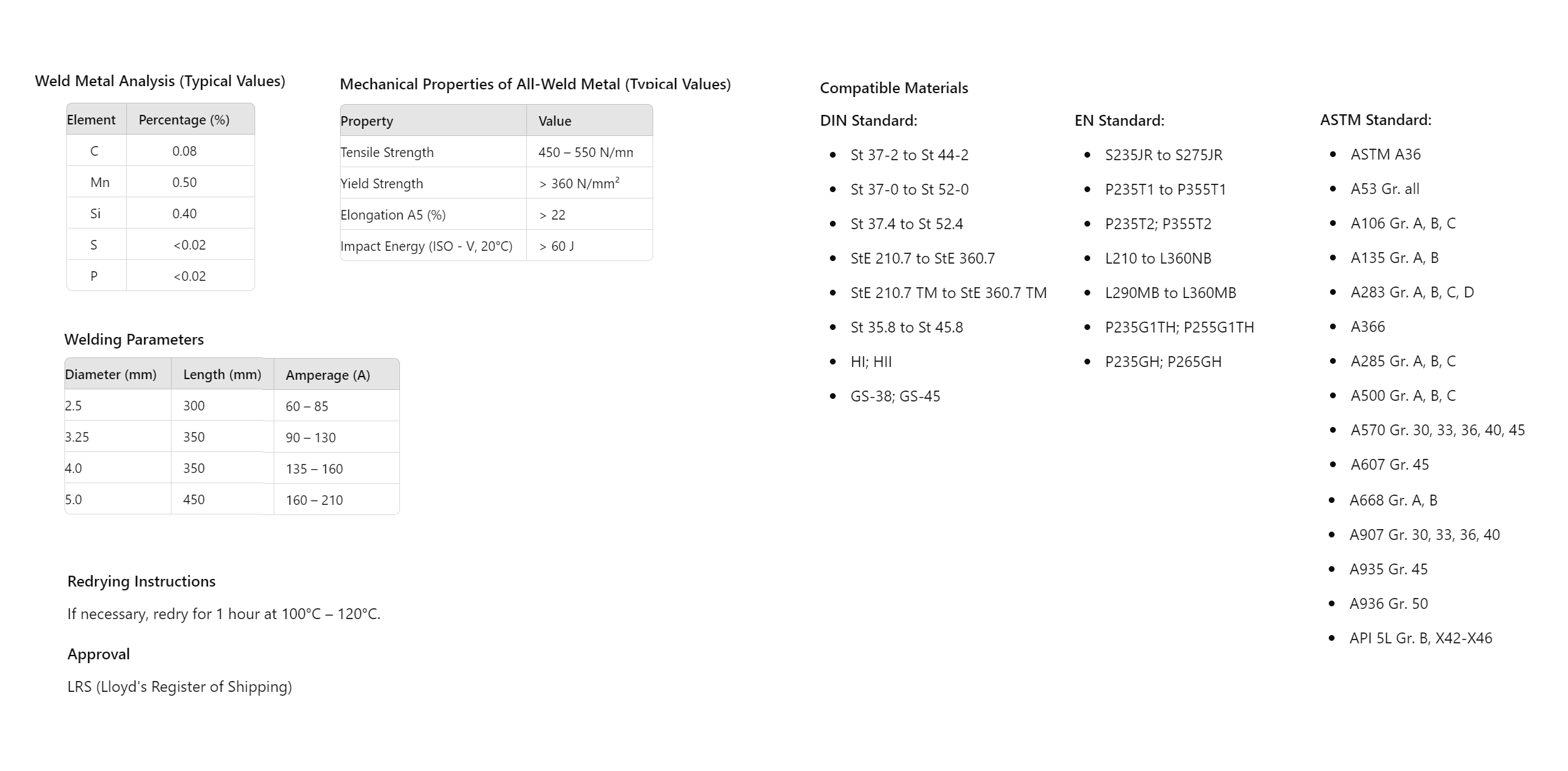

Suitable Welding Currents for E6013 Electrodes

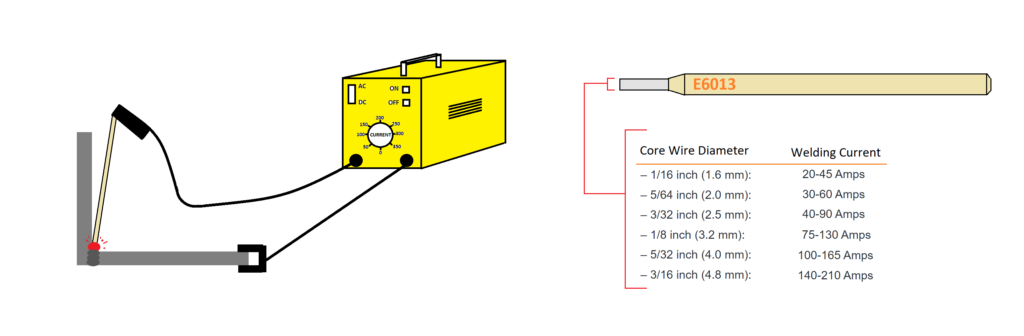

Choosing the appropriate welding current for E6013 electrodes is crucial to ensure optimal performance and weld quality. The suitable welding current varies with the diameter of the electrode. Here are the recommended current ranges for different diameters:

Using the correct current range ensures stable arc characteristics, good bead appearance, and minimal spatter.

Type of Current

E6013 welding electrodes are designed to work with both Alternating Current (AC) and Direct Current (DC). This flexibility makes them suitable for use with a wide range of welding machines, including those that only provide AC power.

Suitable Welding Position

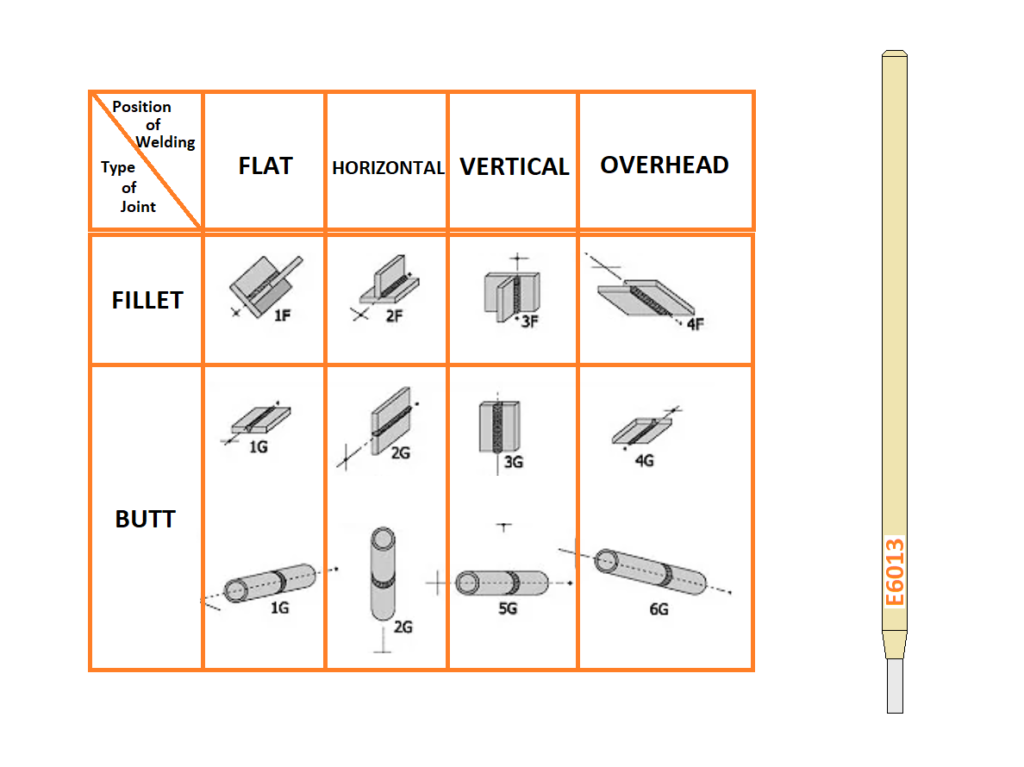

E6013 electrodes are highly versatile and can be used in all welding positions:

– Flat: Ideal for large surface areas and is the easiest position to weld.

– Horizontal: Suitable for welding along horizontal seams.

– Vertical: Can be used for welding vertically up or down, depending on the technique.

– Overhead: Allows for welding from below the workpiece, though it requires good control to avoid spatter and ensure proper bead formation.

Suitable Welding Equipment

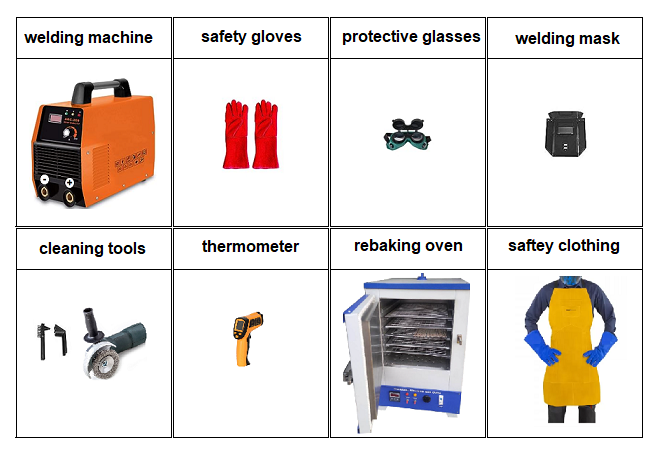

To achieve the best results with E6013 electrodes, the following welding equipment is recommended:

1. Welding Machine: A reliable AC or DC welding machine with adjustable current settings to match the electrode’s requirements.

2. Electrode Holder: A high-quality electrode holder to ensure a firm grip and efficient current transfer.

3. Ground Clamp: A good ground clamp to establish a solid electrical connection with the workpiece.

4. Protective Gear: Appropriate personal protective equipment (PPE), including a welding helmet, gloves, apron, and safety glasses.

5. Chipping Hammer and Wire Brush: For removing slag and cleaning the weld bead after welding.

Proper Packaging of E6013

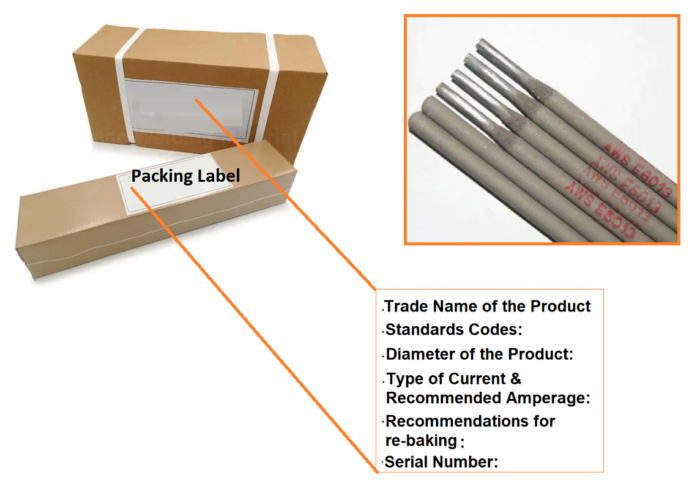

Proper packaging is essential to maintain the quality and performance of E6013 welding electrodes. Here are the key aspects of proper packaging:

– Moisture Protection: Electrodes should be packaged in moisture-resistant materials to prevent them from absorbing humidity, which can lead to poor weld quality and difficulty in starting the arc.

– Sealed Containers: High-quality electrodes often come in sealed containers or vacuum packs to ensure they remain dry and free from contaminants.

– Clear Labeling: The packaging should clearly indicate the electrode type, diameter, and recommended current range. This information helps users select the right electrode for their welding tasks.

– Storage Instructions: Proper storage instructions should be provided to ensure users know how to store the electrodes to maintain their quality.

The packaging of 6013 electrodes usually has a big cardboard box. There are 2 to 4 smaller packages inside this box. To prevent moisture and water penetration, the surface of the boxes is covered with transparent nylon.

Key Consideration for Buyers

When purchasing E6013 welding electrodes, buyers should pay attention to several factors to ensure they get the best product for their needs:

1. Quality: Ensure you purchase high-quality E6013 electrodes from reputable manufacturers to achieve consistent and reliable welds.

2. Storage: Proper storage of electrodes is essential to maintain their quality. Keep them in a dry, moisture-free environment to prevent damage.

3. Compatibility: Verify that the electrodes are compatible with your welding machine and the materials you intend to weld.

4. Quantity: Consider the scale of your project and purchase an appropriate quantity of electrodes to avoid interruptions during welding.

5. Technical Support: Choose suppliers who offer technical support and guidance to help you select the right electrodes for your specific needs.

6. Packaging: Look for electrodes that are properly packaged to protect against moisture and contaminants.

Conclusion

E6013 welding electrodes are a versatile, user-friendly, and cost-effective choice for a wide range of welding applications. Whether you’re a beginner or an experienced welder, these electrodes can help you achieve high-quality welds with ease. By understanding their characteristics, benefits, suitable welding currents, type of current, welding positions, suitable equipment, and proper packaging, you can make an informed decision when purchasing E6013 welding electrodes, ensuring your welding projects are successful and efficient.