Cast Iron Welding Electrode Manufacturing:ENi-CI &ENiFe-CI

This guide is for cast iron welding electrode manufacturing for producers and start-ups who want to make cast-iron SMAW electrodes—especially ENi-CI and ENiFe-CI (AWS A5.15). In simple steps, we cover what goes into the formula, how the process works, the equipment you need, and basic QC.

Introduction to ENi-CI and ENiFe-CI Electrodes

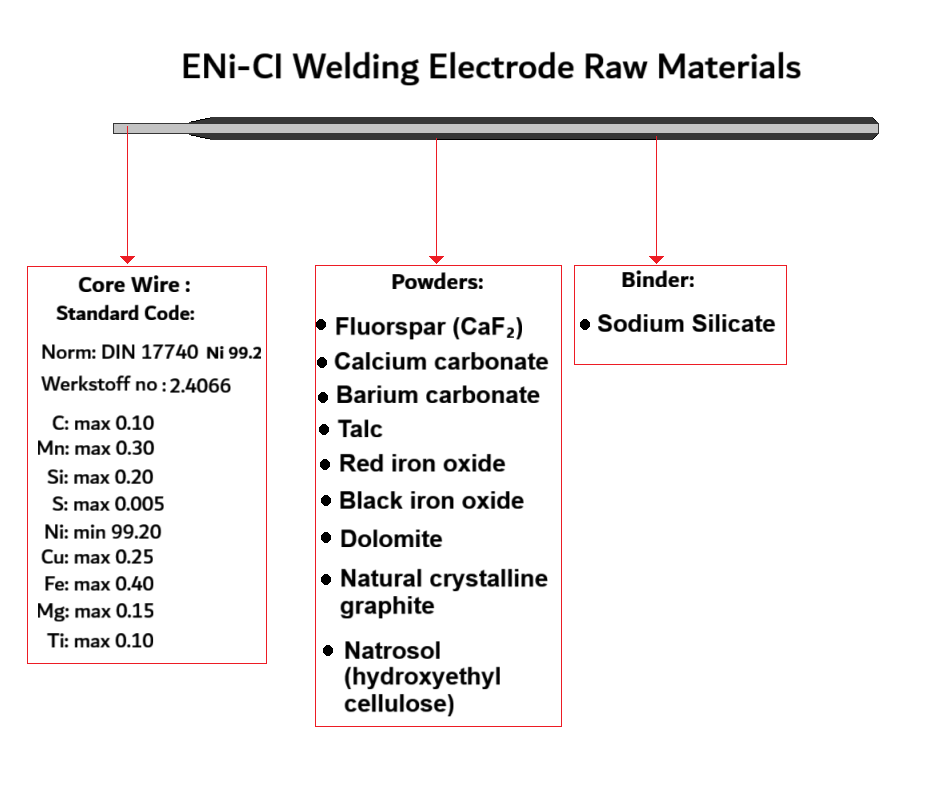

Raw Materials of ENi-CI Electrode

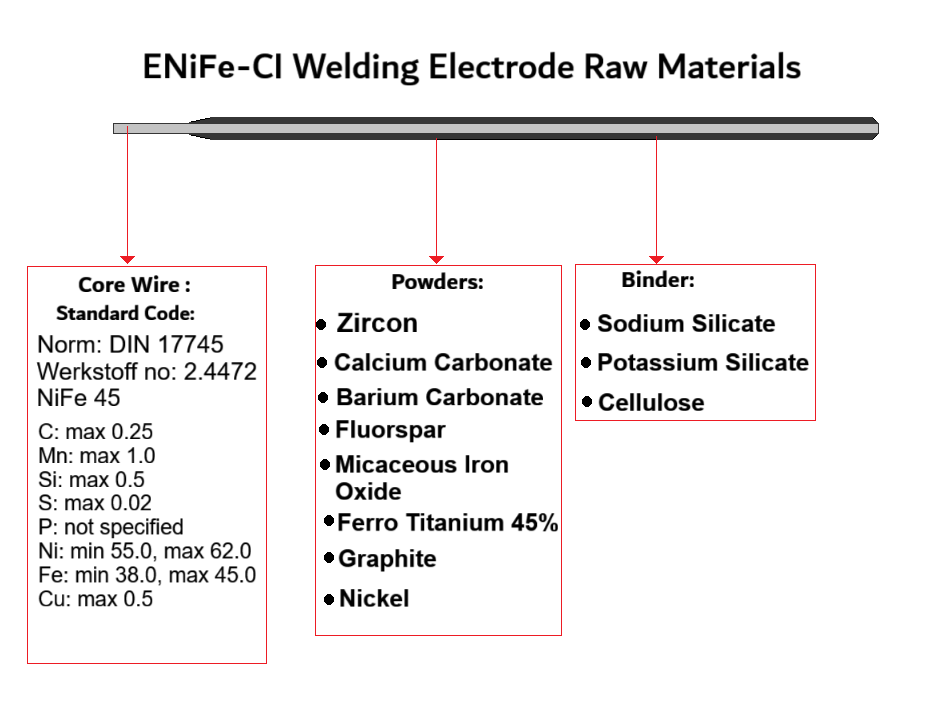

Raw Materials of ENiFe-CI Electrode

Production of ENi-CI and ENiFe-CI Electrodes

Quality Control of the Final Product of ENi-CI and ENiFe-CI Electrodes According to the Standard

Necessary Considerations When Welding Cast Iron

Introduction to ENi-CI and ENiFe-CI Electrodes

ENi-CI and ENiFe-CI are specialized nickel-based welding electrodes designed for the repair and joining of cast iron components. ENi-CI, commonly known as a pure nickel electrode, provides excellent machinability and is ideal for cold welding of gray cast iron where minimal dilution and high ductility are required. It produces soft, easily workable weld metal and reduces the risk of cracking during or after welding. In contrast, ENiFe-CI—a nickel-iron type electrode—offers higher strength and improved resistance to thermal cracking, making it suitable for welding nodular (ductile) cast irons, malleable irons, and even joining cast iron to steel. Together, these two electrode types cover a wide range of cast iron repair applications, from precision engine blocks and housings to heavy industrial castings, combining reliability, mechanical strength, and ease of post-weld machining.

Raw Materials of ENi-CI

Like any other coated electrode, the raw materials include powdered raw materials, binder, and cored wire.

What Each Ingredient Does

Core wire (Ni 99.2%)

High-purity nickel (DIN 17740, 2.4066) keeps impurities very low so the weld runs smooth, resists cracking on cast iron, and stays machinable.

Powder mix (coating ingredients)

-

Fluorspar (CaF₂)

Makes the slag fluid and easy-detaching, improves arc stability/ionization, and helps capture sulfur. -

Calcium carbonate (CaCO₃)

Decomposes to CO₂ for light gas shielding; leaves CaO that raises basicity, helps desulfurize/dephosphorize, and cleans the puddle. -

Barium carbonate (BaCO₃)

Strong arc stabilizer and hydrogen scavenger; buffers moisture effects and helps prevent porosity and undercut. -

Talc (Mg₃Si₄O₁₀(OH)₂)

Tunes slag viscosity and improves bead wetting; also adds plasticity to the green coating so it extrudes without cracking. -

Red iron oxide (Fe₂O₃)

Oxidizing component that refines the puddle, shapes the bead, and influences slag color/texture. -

Black iron oxide (Fe₃O₄)

Similar to red oxide but milder; helps control arc heat and slag detachability, balancing the oxide system. -

Dolomite (CaMg(CO₃)₂)

Source of CaO + MgO to raise basicity, promote crack-resistant, low-hydrogen slag, and improve slag peel. -

Natural crystalline graphite

Adds a touch of carbon to match cast iron, improves machinability, lubricates the arc, and smooths bead appearance. -

Natrosol (hydroxyethyl cellulose, HEC)

Organic rheology modifier for a stable, non-sag coating; burns off cleanly to leave gas channels that steady the arc.

Liquid binder

-

Sodium silicate

The “glue” that bonds the coating; also contributes alkali for easy striking and re-strike, and helps glass the slag.

Watch outs: moisture pickup if curing/storage are poor—keep silicate ratio and drying schedule tight.

the coating blends minerals (for basicity and slag control), oxides (to shape and clean the pool), graphite (for cast-iron friendliness), and tailored binders—so the ENi-CI electrode starts easily, runs stable, peels clean, and leaves a crack-resistant, machinable nickel weld on cast iron.

Raw Materials of ENiFe-CI

ENi-CI is a nearly pure nickel electrode designed for gray cast-iron repairs where you want a soft, very machinable deposit and low cracking risk—ideal for cold repairs, short beads, and buttering. ENiFe-CI is nickel-iron (≈45% Fe), giving a stronger, harder weld with better dilution tolerance and color match to cast iron; it’s preferred for higher-strength joints, multi-pass work, or joining cast iron to steel. Trade-off: ENi-CI → best machinability; ENiFe-CI → higher strength but less machinable.

What Each Ingredient Does

Core wire (NiFe 45 — DIN 17745, Werkstoff 2.4472)

-

Role: Nickel–iron core (≈55–62% Ni, 38–45% Fe) balances crack resistance + strength and tolerates dilution into cast iron and steel.

-

Effect on weld: Stronger and harder than ENi-CI deposits yet still reasonably machinable; better color match to cast iron.

-

Impurity limits (C, Mn, Si, S, Cu) kept low to minimize hot cracking, porosity, and brittleness.

Coating powders (fillers & fluxes)

-

Zircon (ZrSiO₄): High-melting slag former → smooth bead, glassy protective slag, porosity control.

-

Calcium carbonate (CaCO₃): Gives CO₂ shielding; CaO raises basicity, helps desulfurize/dephosphorize, improves slag release.

-

Barium carbonate (BaCO₃): Strong arc stabilizer and hydrogen scavenger; buffers moisture effects.

-

Fluorspar (CaF₂): Fluxing/ionizing agent; lowers slag melting point, increases fluidity, aids desulfurization.

-

Micaceous iron oxide: Plate-like oxide that shapes bead, moderates arc heat, and helps slag peel.

-

Ferro-Titanium 45%: Powerful deoxidizer/denitrogenizer; refines grain, reduces porosity and hot cracking, improves fusion on CI/steel.

-

Graphite (natural crystalline): Adds controlled carbon for cast-iron compatibility and machinability; lubricates arc, improves wetting/smoothness.

-

Nickel powder: Tunes deposit toward Ni-Fe target chemistry, boosting ductility and crack resistance vs iron-rich deposits.

Binders (liquid/organic)

-

Sodium silicate: Primary binder—green strength and adhesion; contributes alkali that aids easy striking/re-strike and helps glass the slag.

-

Potassium silicate: Similar bonding with stronger arc ionization (K⁺ favors stable arcs), improving AC performance and start ability.

-

Cellulose (HEC or similar): Rheology modifier for smooth extrusion and anti-sag; burns off to create gas channels that steady the arc.

The Ni-Fe core delivers strength and dilution tolerance; the powder blend controls arc, chemistry, and slag behavior; and the silicate/cellulose binders hold the coating and fine-tune ignition and handling—together giving ENiFe-CI its tougher, reliable performance on cast iron.

Production of ENi-CI and ENiFe-CI Electrodes

The production workflow for these two electrode types does not differ from conventional SMAW electrodes. For a detailed review of the standard process, see [Article 1] and [Article 2].

Below are several points specific to these electrodes that manufacturers should consider.

As outlined elsewhere on this site, SMAW electrodes are produced using either screw or hydraulic extruders. For this specific electrode type, production is feasible only with a hydraulic extruder. Thanks to lubricants such as graphite, talc, and Natrosol, extrusion is straightforward. However, these electrodes are highly prone to cracking; avoid thermal shock during ambient drying and oven baking by using controlled heating.

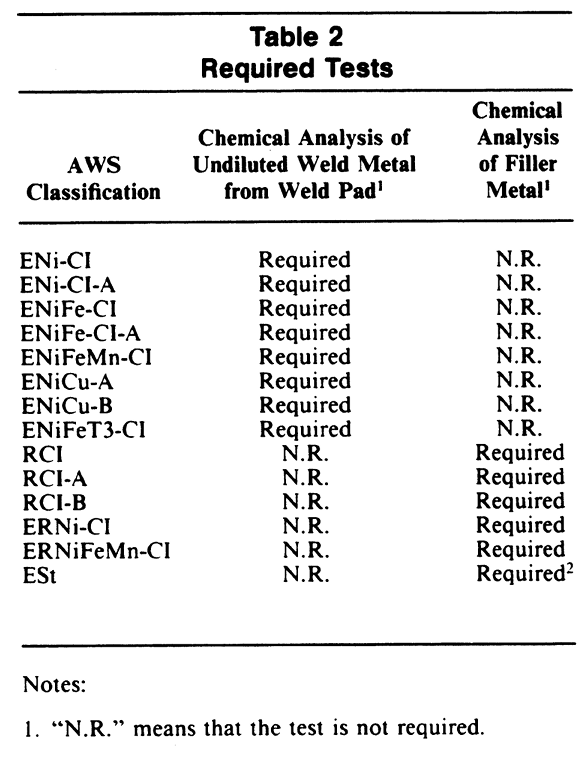

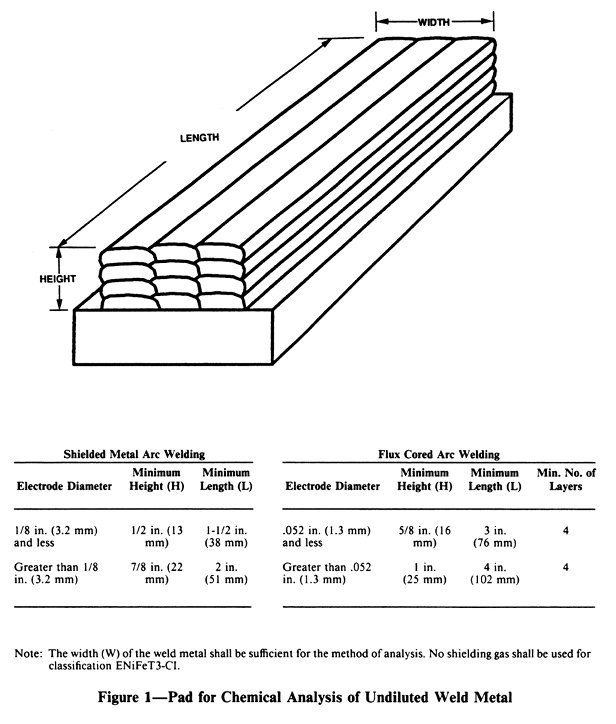

Quality Control of the Final Product of ENi-CI and ENiFe-CI Electrodes According to the AWS A5.15 Standard

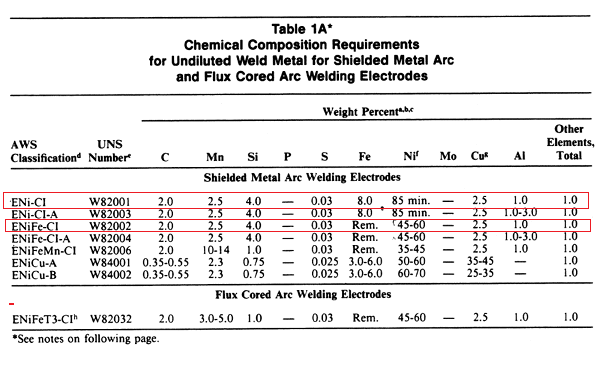

The AWS A5.15 Standard specifically specifies which tests should be used to determine the quality of these two types of electrodes. Table 2 on page 4 states that the only test required for these two types of products is chemical analysis.

Another important point is that this standard does not require chemical analysis for these two electrodes, and it is only required for the Est electrode.

To test ENi-CI and ENiFe-CI under AWS A5.15, you first make a small weld pad exactly like the standard shows, then take metal shavings from the clean, undiluted weld metal and do a chemical analysis. If the chemistry matches the limits for the class you’re making (ENi-CI or ENiFe-CI), you’ve passed the core requirement.

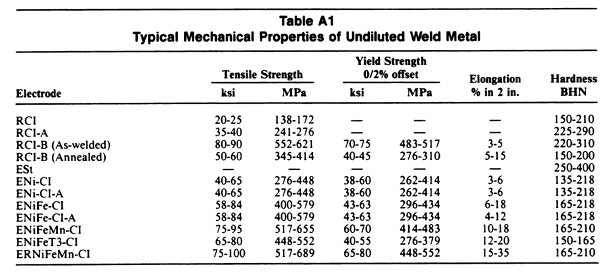

The manufacturers of these two types of electrodes, in addition to the chemical analysis of the weld metal, also state mechanical properties for them. The standard also states these specifications on page 18, Table 1A. Although these properties are optional, in order to compete with other manufacturers, it is necessary to examine these properties and state them in the product certificate.

Necessary Considerations When Welding Cast Iron

Welding cast iron often presents problems because, unlike steel, it contains high amounts of carbon, phosphorus, and silicon, and it lacks elasticity. It is recommended that, before welding, the surface be cleaned of paint, oil, rust, and other contaminants. Cracks that may form due to thermal stresses in cast iron or due to weld bead contraction can be mitigated by using intermittent (skip) welding and stopping the weld several times.

Light peening on 2-centimeter beads immediately after welding is beneficial. The workpiece at the weld area should never become hotter than what can be comfortably tolerated by hand. In general, use the lowest practical current, avoid weaving, and lay down thin beads. If there is a risk of the joint overheating, stop welding. Under no circumstances should cooling be accelerated by quenching or exposing the part to air flow (e.g., blowing compressed air). The cast-iron part should be fully protected from drafts. If preheating is needed, it may be applied up to a maximum of 300 °C.

Large cast-iron parts must be heated cautiously and gradually; after finishing the weld, hot sand should be poured over the area. This electrode runs smoothly and uniformly, seals the joint with adequate penetration, and produces little slag. The cast iron and weld metal fuse deeply with each other, and both materials—as well as their junction—can be filed and machined.