Development of New Welding Materials on the Base of Mathematical Modeling of Metallurgical Processes

Part 2. Development of Solution Algorithm and Software.

M.Zinigrad , V. Mazurovsky

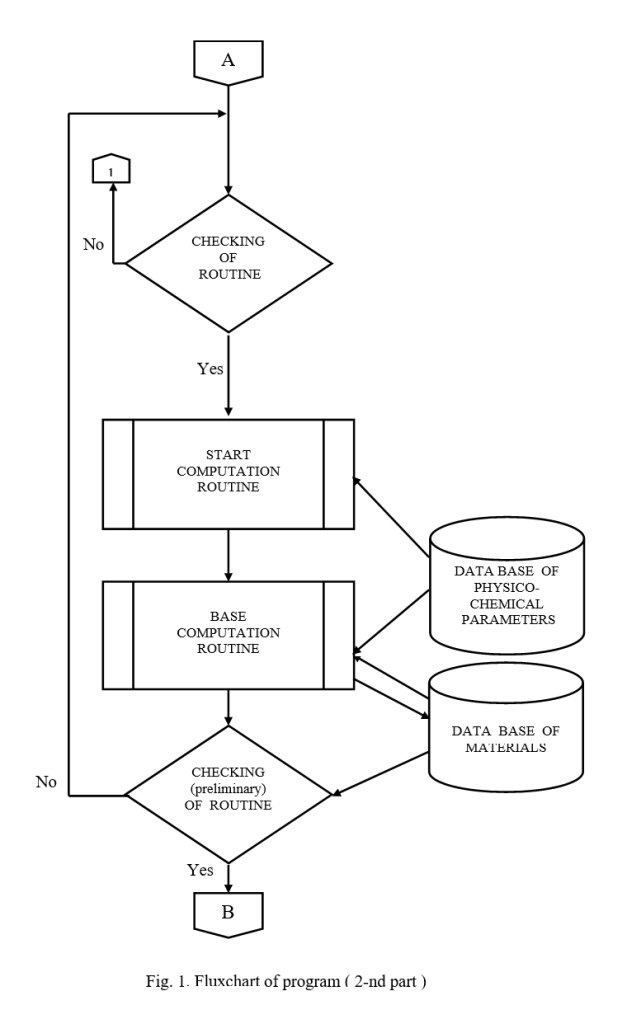

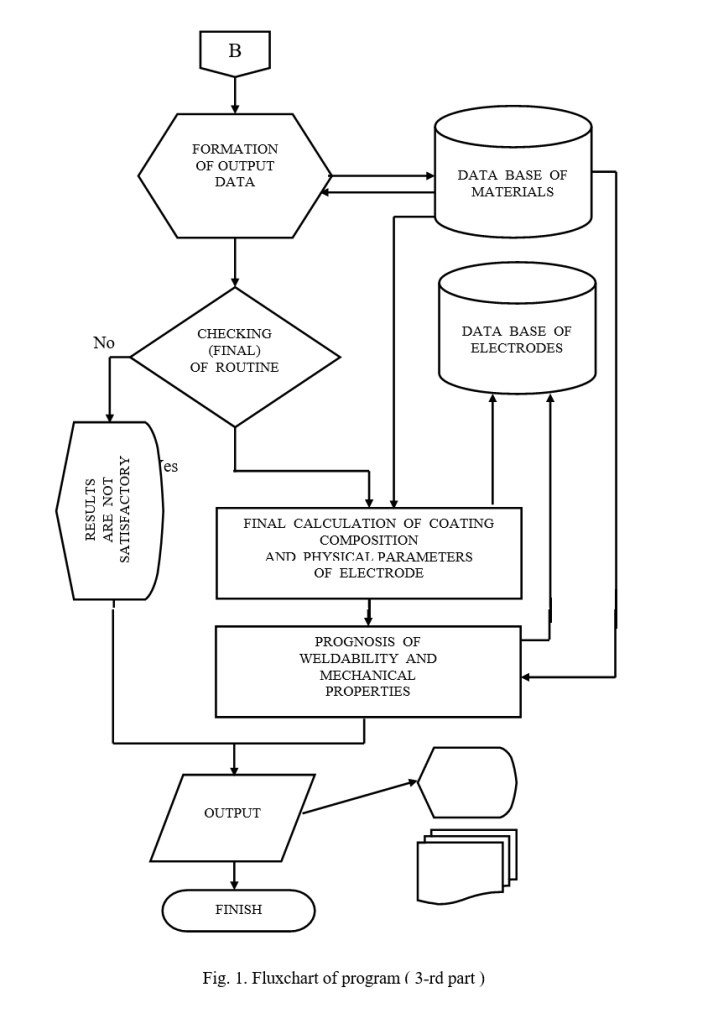

The solution of “the inverse problem” (which was described in Part 1) can be implemented basing on the broad range of software, according to the specific aim(s) of the researcher. In our case we used Visual Basic Application for Microsoft Excel (both for Windows 3.11 and Windows 95) taking into consideration the fact that, on the one hand, Microsoft ideology is popular among PC users and, on the other hand, the large amount of cumbersome cyclical computations can be easily organized with Microsoft Excel spreadsheets. Besides, Microsoft Excel allows to form easily manageable dynamic data bases for the storage of data and parameters used in the process of computations. The program’s structure consists of 123 program modules, 29 linked spreadsheets and 5 auxiliary data bases functionally integrated into 3 data bases. The execution sequence of program modules and computations in spreadsheets as well as the access to data bases are managed by the main program module. The user can intervene in the process through the user-friendly interface.

The program offers:

- The computation of electrode coating composition necessary for the required chemical composition of built-up metal in the specific built-up layer, i.e. the new formula of electrode.

- The computation of built-up metal composition in any built-up layer, with the specified composition of electrode coating.

- The forecast of mechanical properties of built-up metal.

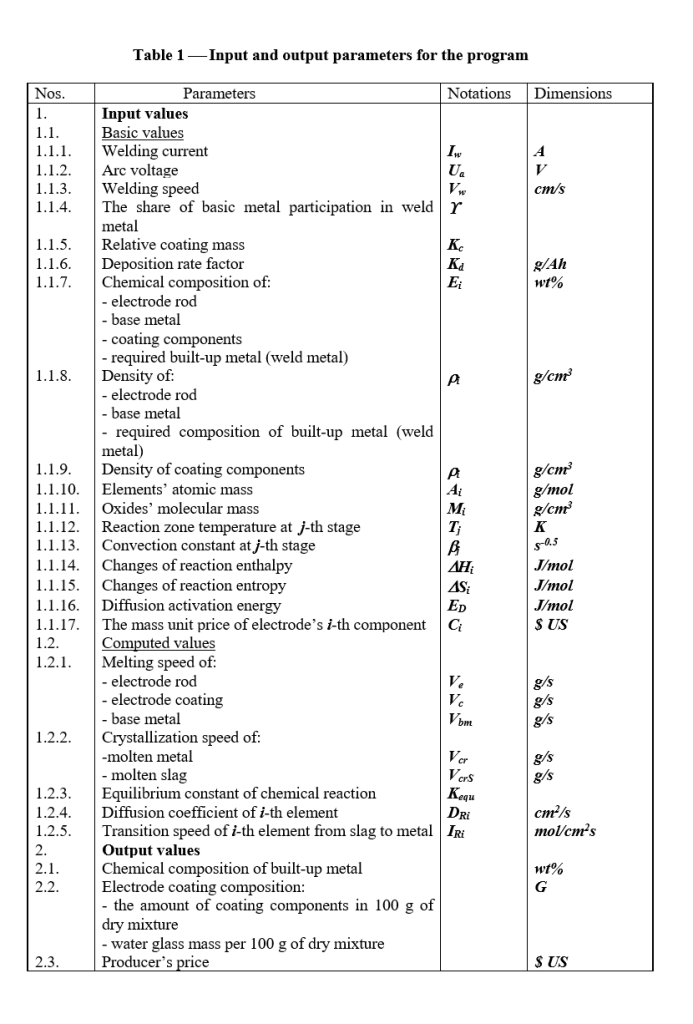

- The forecast of technological weldability (the susceptibility to hot and cold cracks under the influence of welding thermal cycle as well as to cracks caused by the subsequent thermal treatment). Input and output parameters of the program were formed basing on the characteristics of the electrode under development (Part 1). The structure of program parameters is presented in Table 1.

All input parameters are functionally classified and stored in respective data bases.

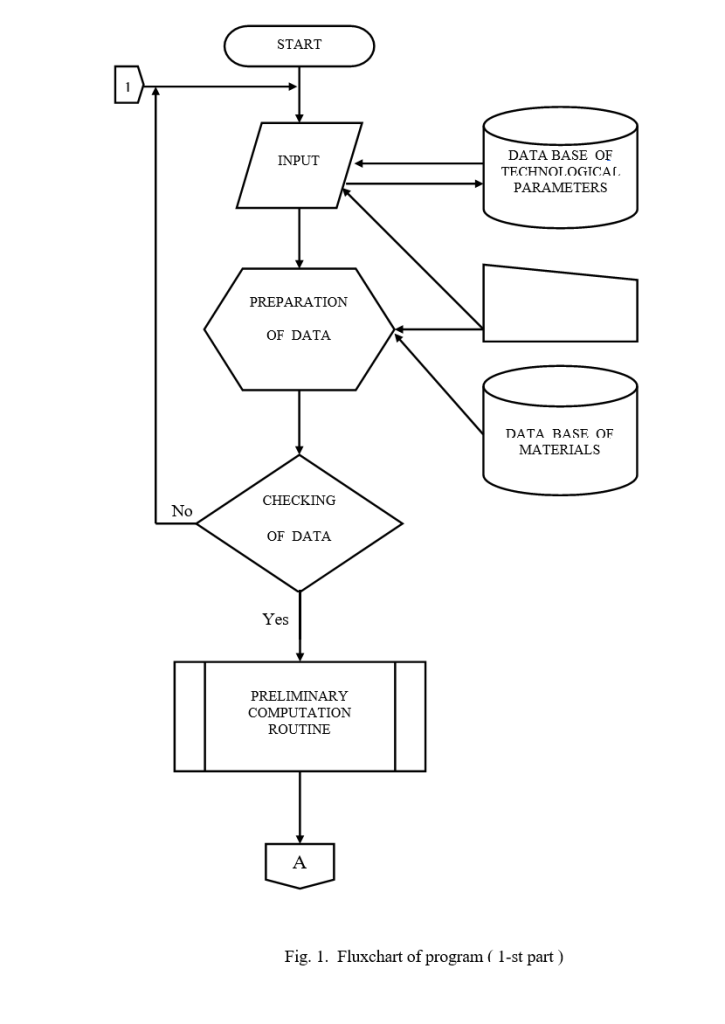

The running program task is presented as a flux chart – see Fig.1.

Below we offer a step-by-step description of program implementation using as an example the actual case of computing the electrode coating composition.

Steps in the program

1-We assume that our task is to develop a new electrode (i.e., a new electrode coating composition) for obtaining a weld metal with an assigned composition and required properties. We assume that we are dealing with the manual arc welding of steel St-37a (as the base metal). The chemical composition of this steel, which is needed for the calculation, is stored in the database together with the compositions of other standard materials.

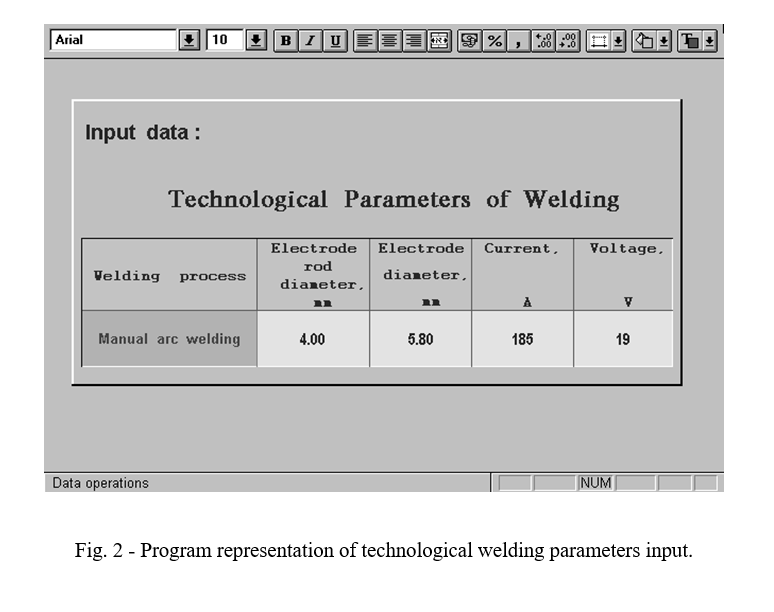

The technological parameters of the welding process must also be determined.

We enter the technological parameters in accordance with the welding procedure selected.

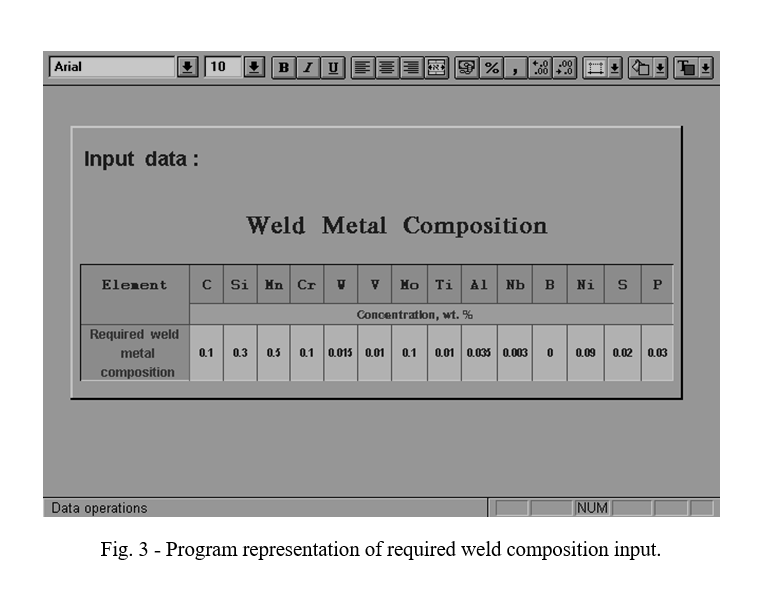

We must ensure that the weld metal has a definite composition.

We enter the chemical composition of the weld metal that must be obtained (Fig.3).

2-To solve the problem, the material of the electrode rod must be selected and the optimal composition of the electrode coating must be determined, i.e., a new electrode formula must be developed.

2-1-We choose, for example, the simple welding wire WR-Fe-70/50-06 as the rod material. The choice of a simple wire is stipulated primarily by economic considerations. Since we intend to use industrial wastes that contain alloying and slag components to develop the new electrode, there is no need in this case to use an alloyed (i.e., more expensive) wire. (Of course, to obtain a weld metal with a high degree of alloying, it will be necessary to use an alloyed wire.)

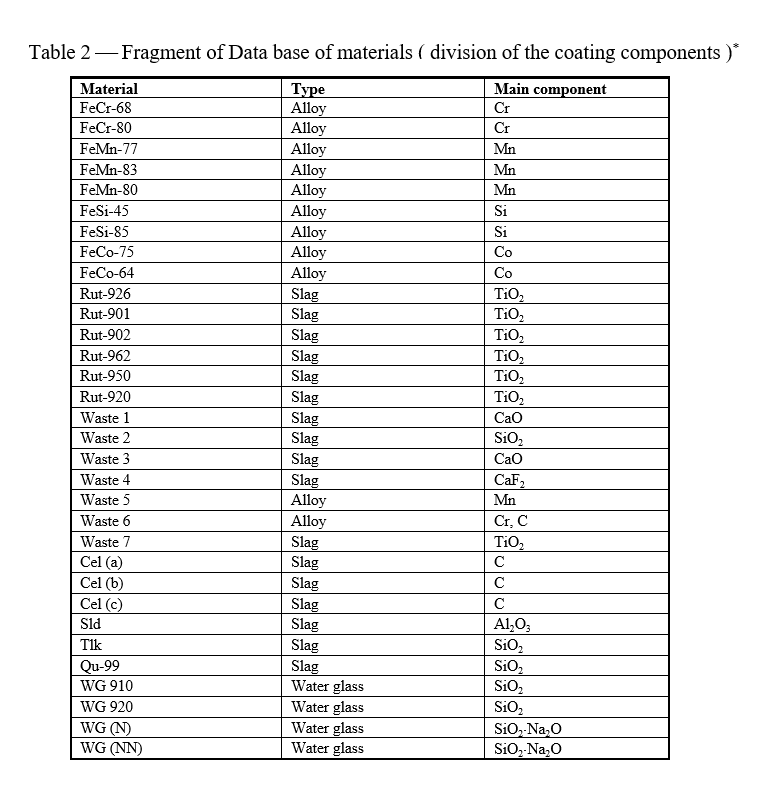

2-2-The next and most important step is optimization (which, in the case at hand, is essentially development) of the electrode coating composition. The required joint composition can clearly be obtained with different combinations of components in the coating. The database contains the chemical compositions of various components (alloying and slag), which should be utilized in selecting the optimal electrode coating composition. We present some of the materials needed for our case.

* We note that industrial wastes (which we have been designated as Waste 1, Waste 2, Waste 3,etc. in Table 2) are materials which actually exist, but have not hitherto been used for such purposes.

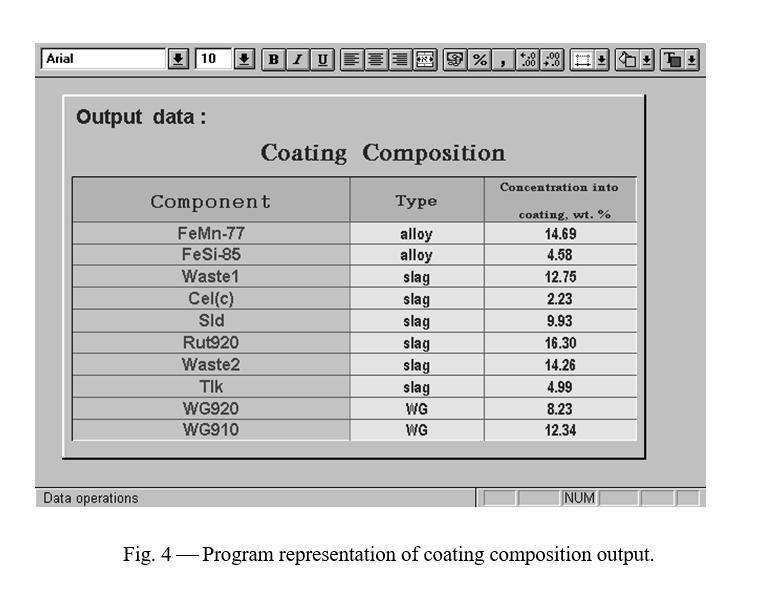

The program has to determine the electrode coating composition that provides the required weld metal composition (Fig. 3 ) and to select the most inexpensive variant among them. This clearly requires a large number of iterations to perform calculations with all the possible component ratios. In particular, four coating compositions were found for the case under consideration, and one of them was specified as the coating which provides the required weld composition with the lowest production costs. The results of the calculation (both the optimal composition and the other three compositions) are stored in the database of the program. We present only the optimal coating composition (Fig. 4).

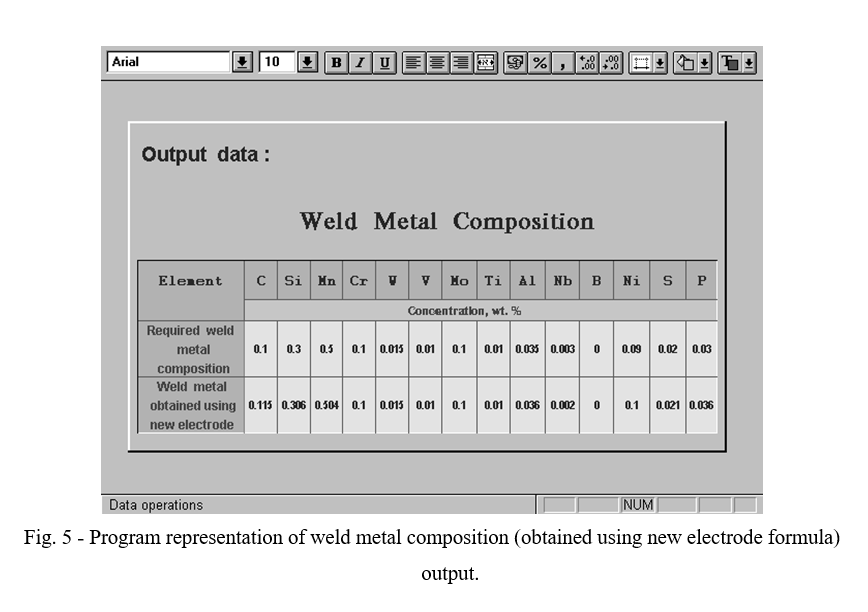

3-Such a coating provides the solution for the problem posed, i.e., the required weld metal composition. This composition agrees well with the composition which we assigned when we posed the problem (Fig. 5.).

Closer agreement between the required and calculated compositions can clearly be provided, but this would require a larger number of iterations and, accordingly, a greater amount of computer time.

4-The program includes a special module, which provides an evaluation of the weldability and mechanical properties of the joint metal having the composition obtained.

5-The approximate time for the calculations and optimization was 15-20 min. in the case considered. The result is a new formula for an electrode that provides an assigned joint composition and is 40-50% less costly than the existing formulas owing to the employment of waste materials and optimization of the composition.

The cost reduction will be even more significant in the case of high-alloy steels and other expensive metals and alloys.

Conclusion

–The algorithm for the forecast of the final composition of built-up metal (weld metal) basing on the known electrode formula in any built-up layer had been developed.

–The algorithm for the computation of the optimal electrode coating composition had also been developed which allows to specify the preset composition of built-up metal in the preset built-up layer.

–On the basis of these algorithms the programs were developed to provide:

- a) the computation of built-up layers’ chemical composition for manual arc welding of steels and nickel-based alloys using coated electrodes;

- b) the computation of optimal composition for electrode coating, with the following preset parameters:

– welding conditions;

– chemical composition of electrode rod and base metal;

– required chemical composition of built-up metal.

Know-More